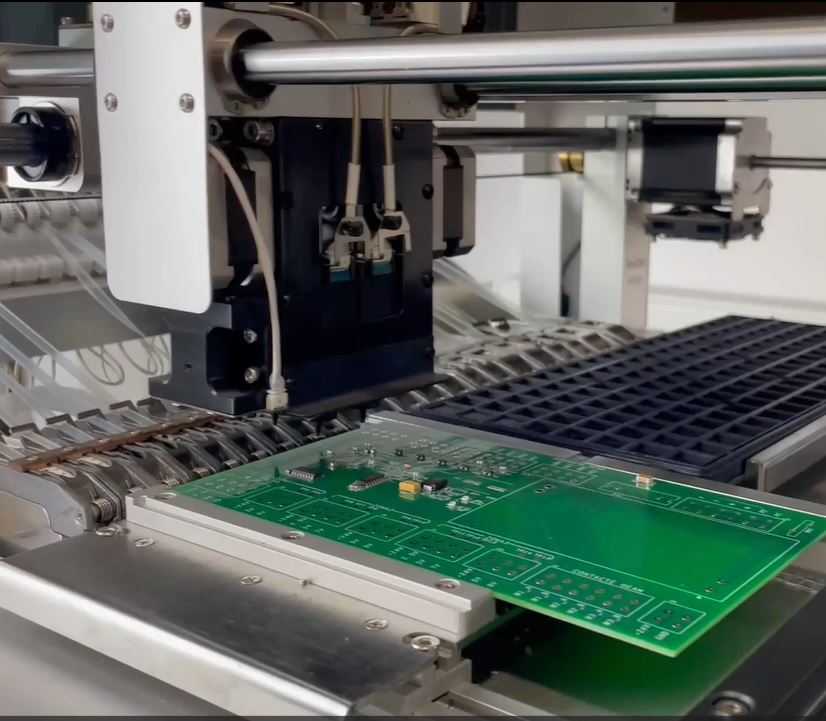

SMD: Pick and place machine

Pick and Place for PCB Assembling:

SMD components mounting with a Pick-and-Place machine

Surface-mount technology (SMD) assembly using a Pick-and-Place machine has become the industry standard in modern electronics manufacturing.

This automated process offers significant advantages compared to manual component placement.

Pick-and-Place machines position components with extremely high accuracy, ensuring correct alignment even for very small components.

This reduces placement errors and improves overall product reliability.

Unlike manual assembly, automated placement delivers repeatable and uniform results.

Every PCB receives the same level of precision, minimizing variability between products.

Modern electronic devices require increasingly smaller components.

Pick-and-Place machines can handle micro-size SMD parts that are nearly impossible to place manually.