Our services

For Individuals

• with our experience we can perfectionate your idea

• we can advise, how to manufacture it cost effectively

• friendly and flexible communication

• 3D design and modelling

• rapid prototyping

• MOQ from 1 pcs

For Startups and Kickstarters

• competitive price

• rapid prototyping

• easy communication

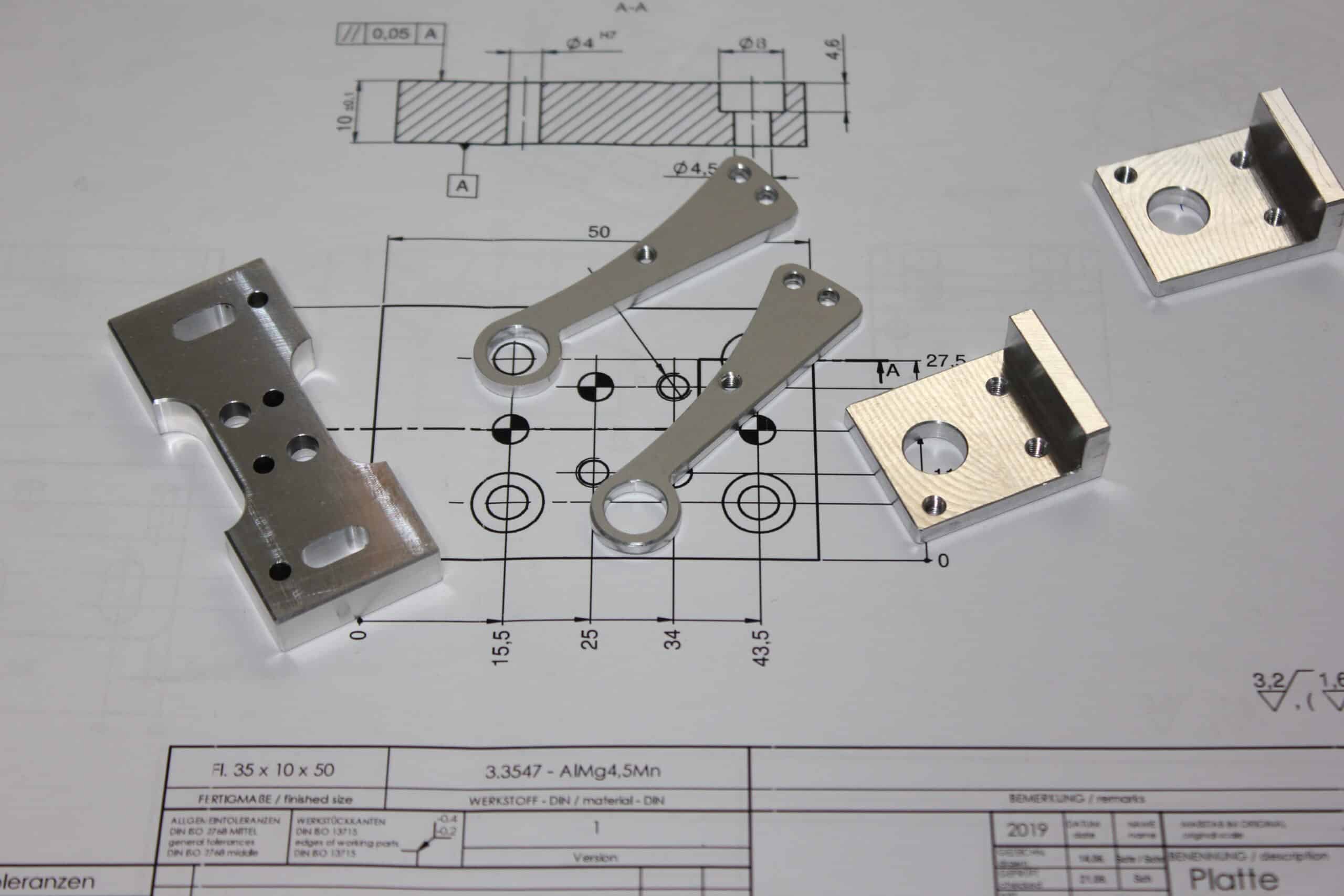

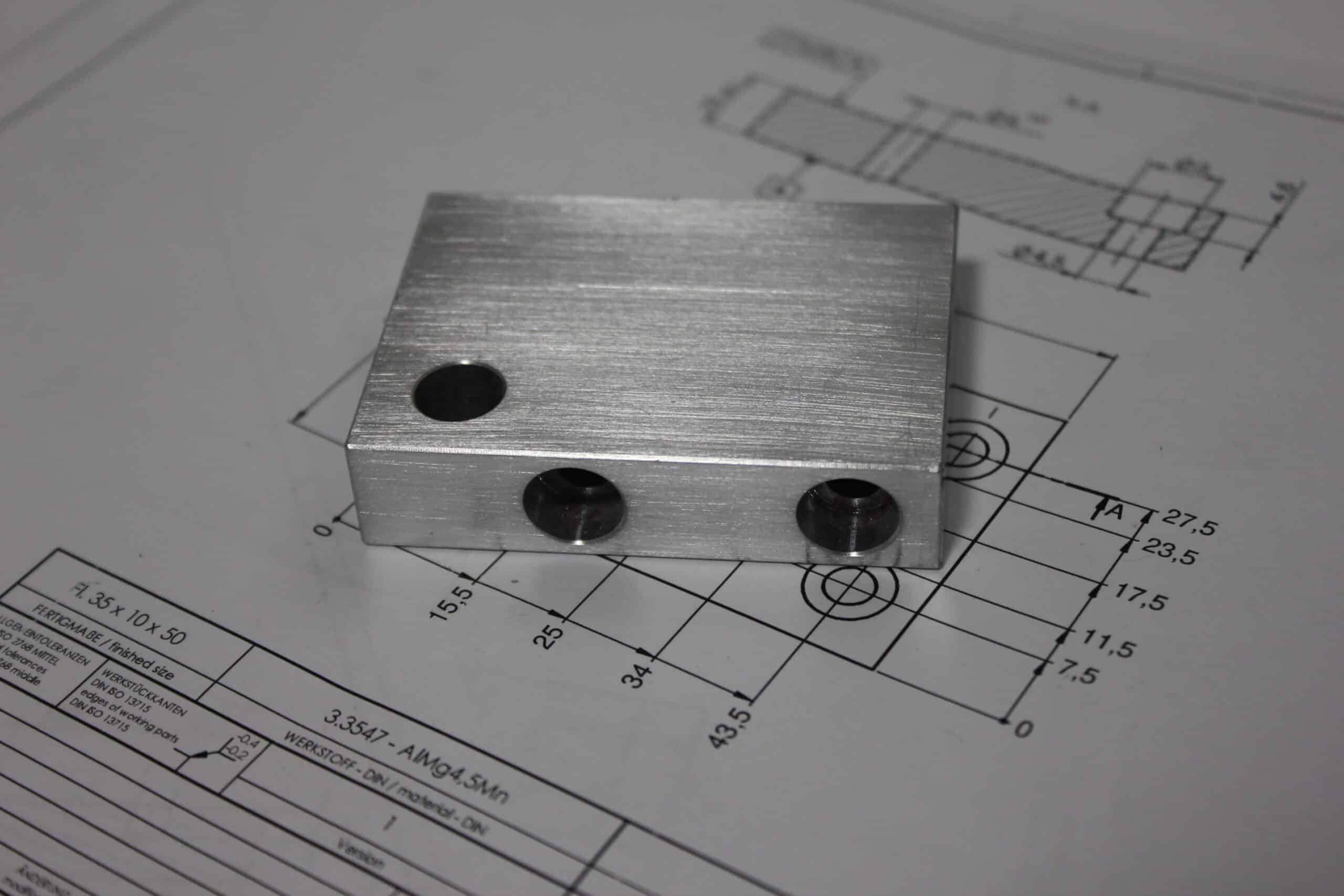

• preparation of documentations and mechanical drawings

• 3D design and modelling

• searching for solutions to a cost effective manufacturing

• preparing for the mass production

• help in building a Kickstarter campaign

• serious about deadlines

For Big companies

• time efficient manufacturing small and middle volumes

• mechanical and electrical assembly

• shipping worldwide

• wide range of material

• professional team

Our machines

Haas VF1 Vertical Machinig Centre

Specifications

• Travel X-axis: 508 mm

• Travel Y-axis: 406 mm

• Travel Z-axis: 508 mm

• Spindle: 7500 rpm

• Tool capacity: 20

• Spindle motor power: 22.4 kW

Haas VF-2SS Vertical Machinig Centre

Specifications

• Travel X-axis: 762 mm

• Travel Y-axis: 406 mm

• Travel Z-axis: 508 mm

• Spindle: 12000 rpm

• Tool capacity: 30

• Spindle motor power: 22.4 kW

Haas VF-2SSYT Vertical Machinig Centre

Specifications

• Travel X-axis: 762 mm

• Travel Y-axis: 508 mm

• Travel Z-axis: 508 mm

• 4th- and 5th-axis operations

• Spindle: 12000 rpm

• Tool capacity: 30+1

• Spindle motor power: 22.4 kW

Haas ST-15Y High-performance Turning Center

Specifications

• Travel X-axis: 200 mm

• Travel Y-axis: ± 51 mm mm

• Travel Z-axis: 406 mm

• Chuck size: 210 mm

• Bar capacity: 64 mm

• Spindle: 4000 rpm

• Tool capacity: 12 (6 VDI; 6 BOT)

• Spindle motor power: 14.9 kW

Haas UMC-500SS 5-axis Vertical Mill

Specifications

• Travel X-axis: 601 mm

• Travel Y-axis: 406 mm

• Travel Z-axis: 406 mm

• B Axis – Tilt

• C Axis – Rotate

• Spindle: 12000 rpm

• Tool capacity: 30+1

• Spindle motor power: 22.4 kW

QUALITY PROTOCOL

WHAT IS MORE IMPORTANT FOR YOU

The number of machines we have or the quality that we produce ?

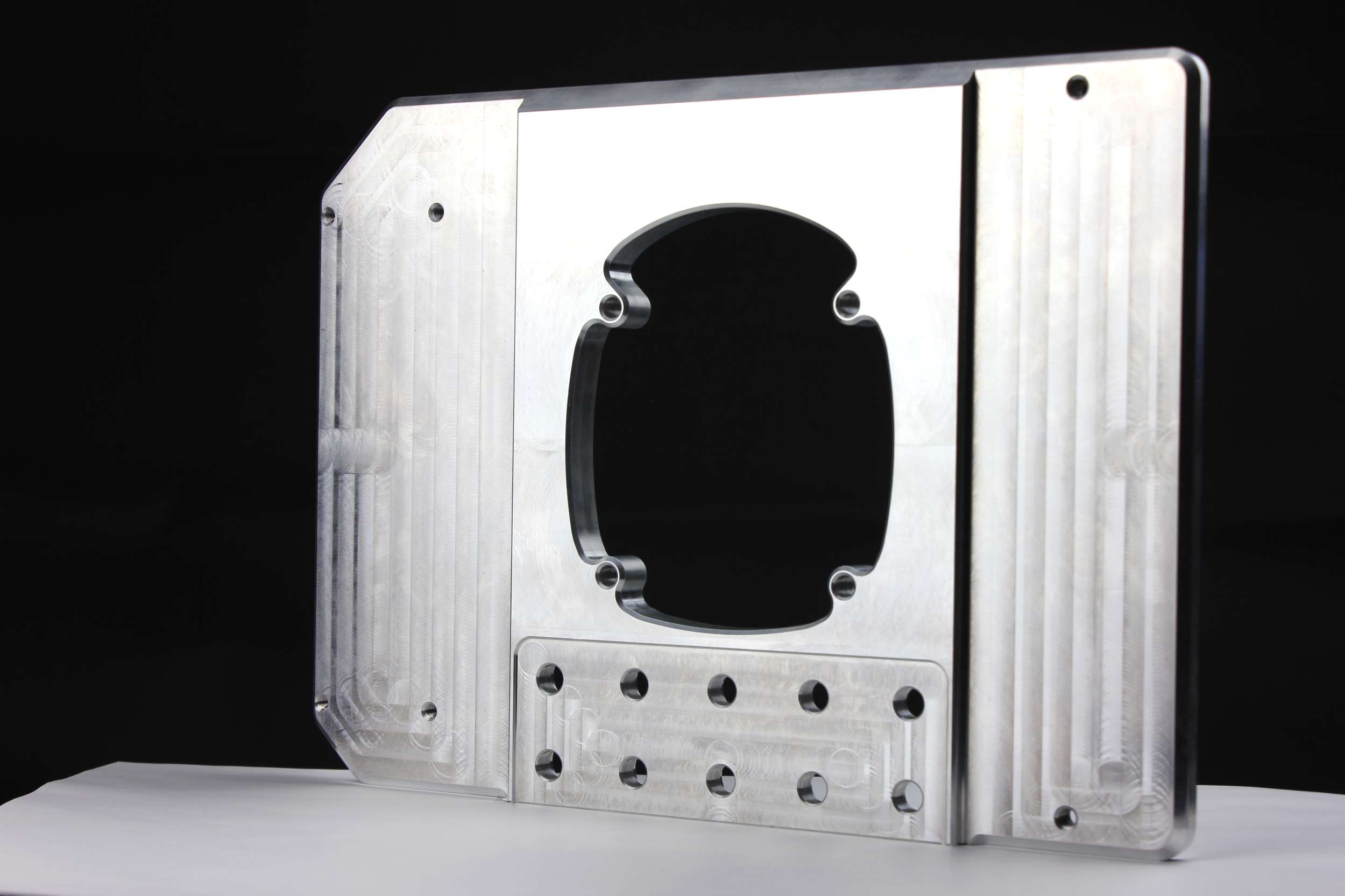

Scratch and dents free

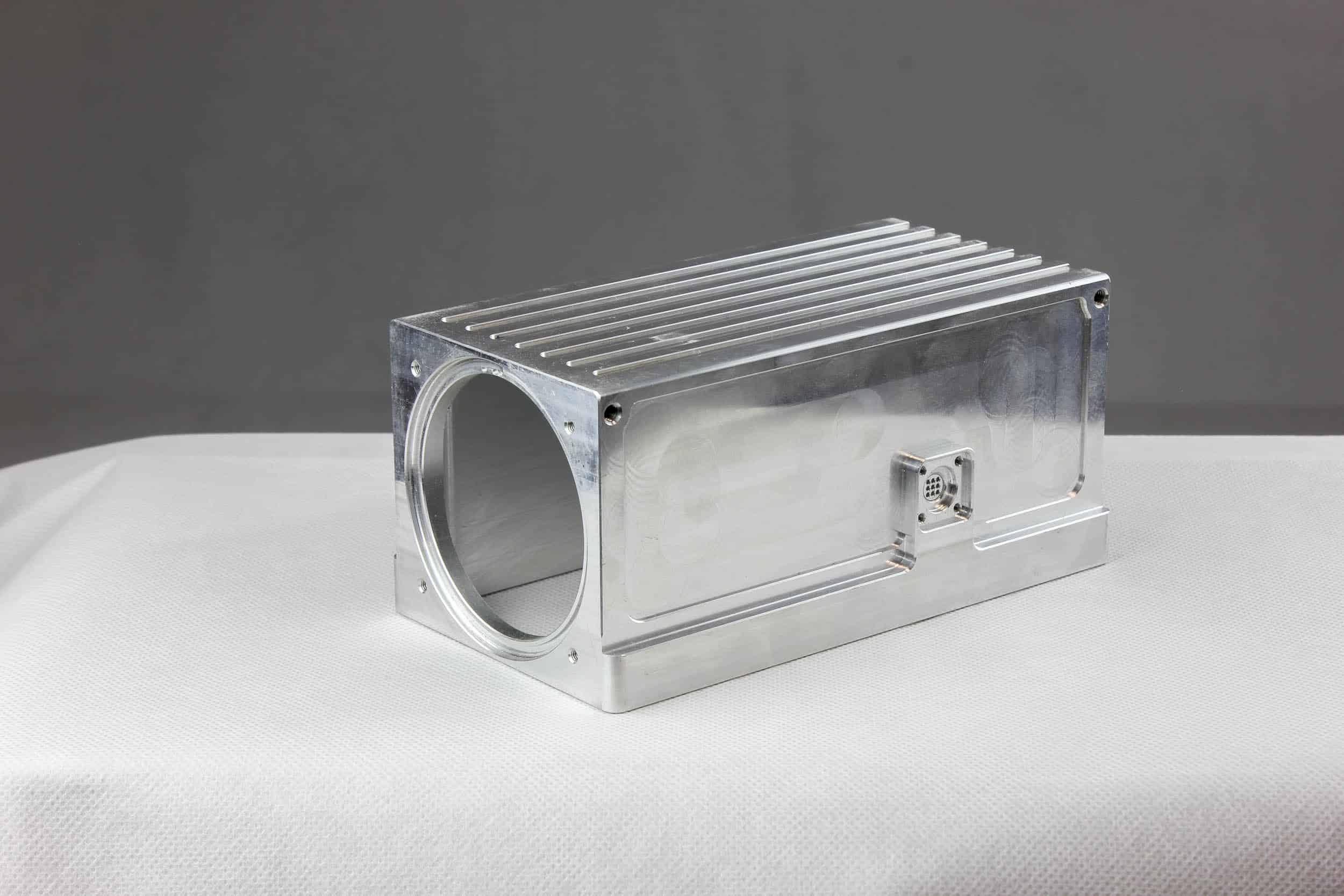

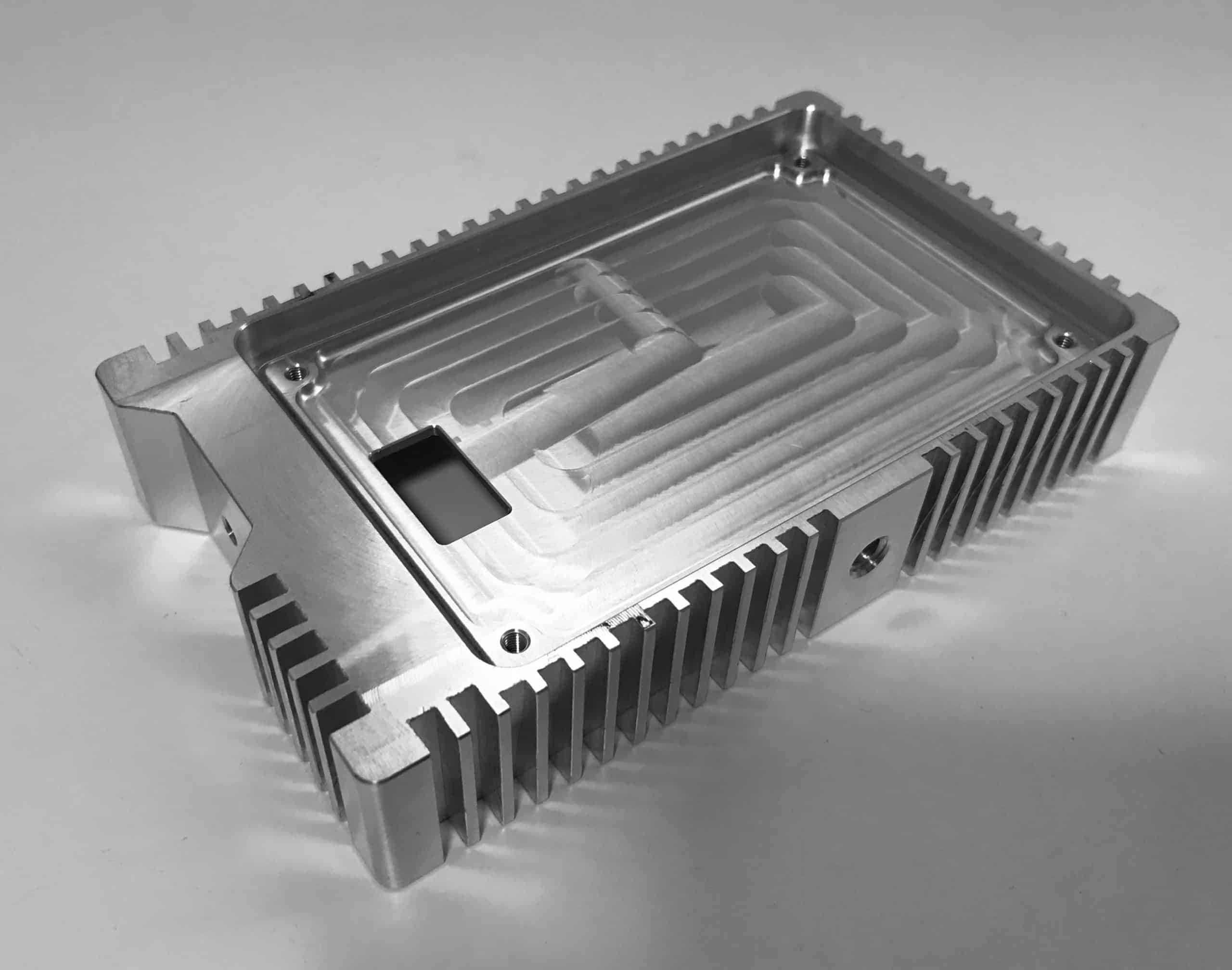

We are always very careful not to leave any scratch on the parts and to make sure that the vice and clamps don’t make any dents either. We have made several electronic enclosures where optical appearance is highly important.

Clean and chip free parts

We carefully clean every hole and thread on the parts and remove the coolant liquid, leaving no stain on the part to prevent corrosion.

Machined edges

Parts can not be left with sharp edges and making the edges by hand is not acceptable. We take the extra time and make all the edges by machine to be perfect.

Quality check

No part can leave our facility without going through our inspection room. The inspector fills out the quality documents with the measured values and signs the quality protocol document.

INSPECTION

To ensure high quality.

Every part goes through our inspection room where the inspector has to measure the part and fill the quality document with the measured values. For the inspection we are using inside and outside micrometers, thread gauges hole gauges, precision calipers. Although we don’t have a 3D measuring machine YET, we are in contract with local company who can measure the parts for us and provide proof of measuring with 3D measuring system if required? We are constantly growing our inspection tools and aiming for perfection in every step of our work.

OUR MOTTO

“Deliver on time and never get claim”

100+

Parts delivered

5+

Satisfied customers

1+

Experience in years

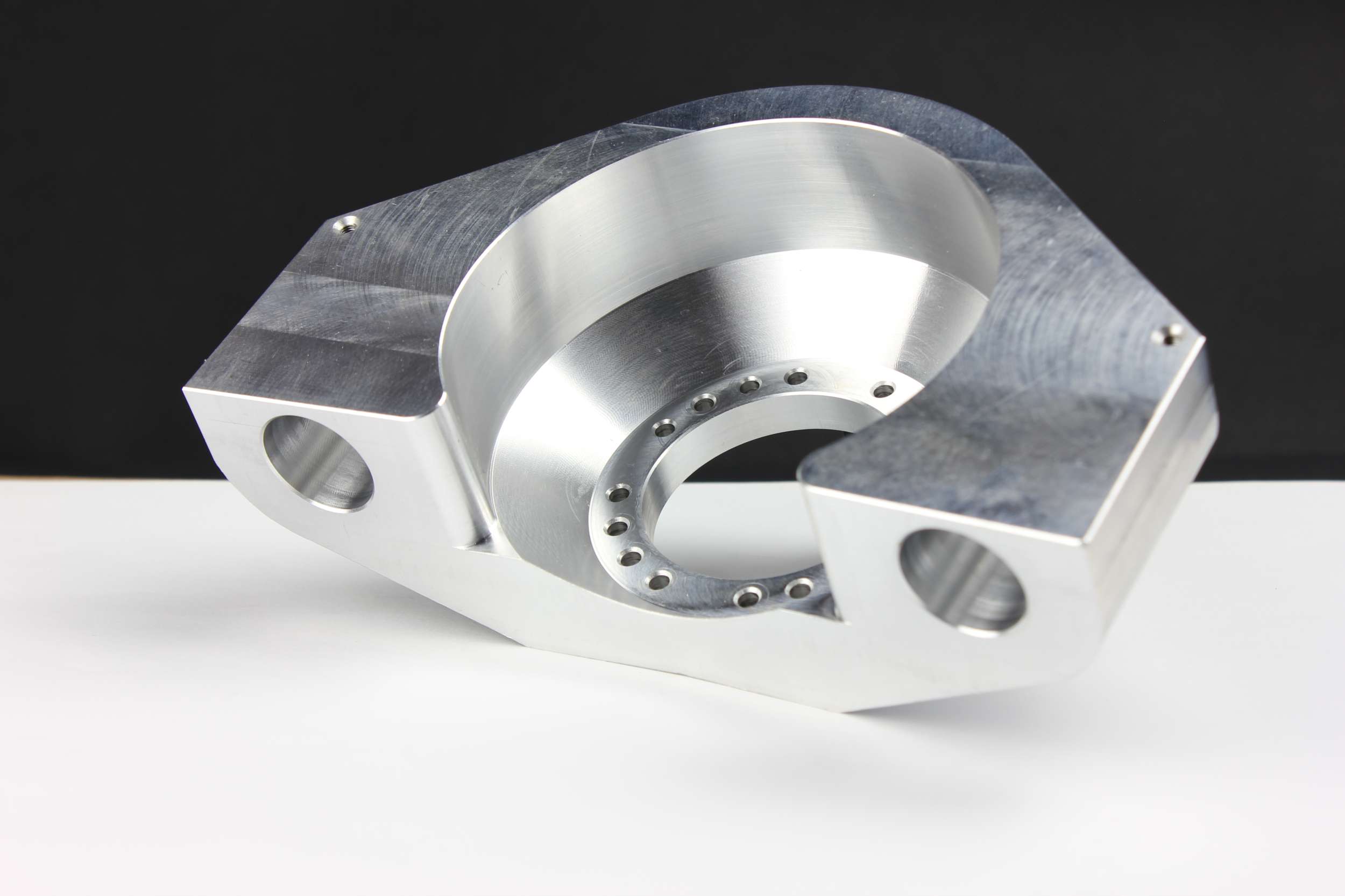

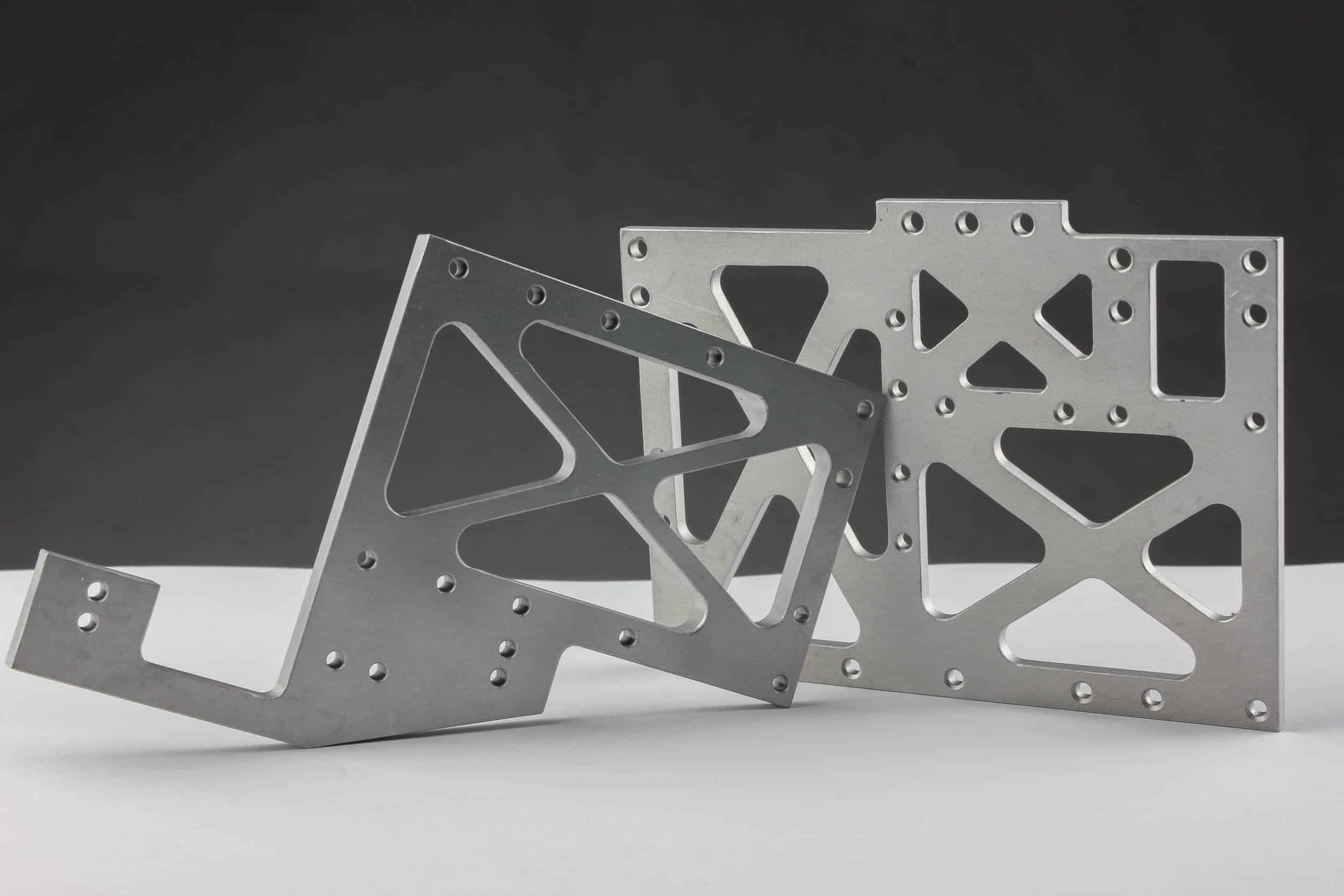

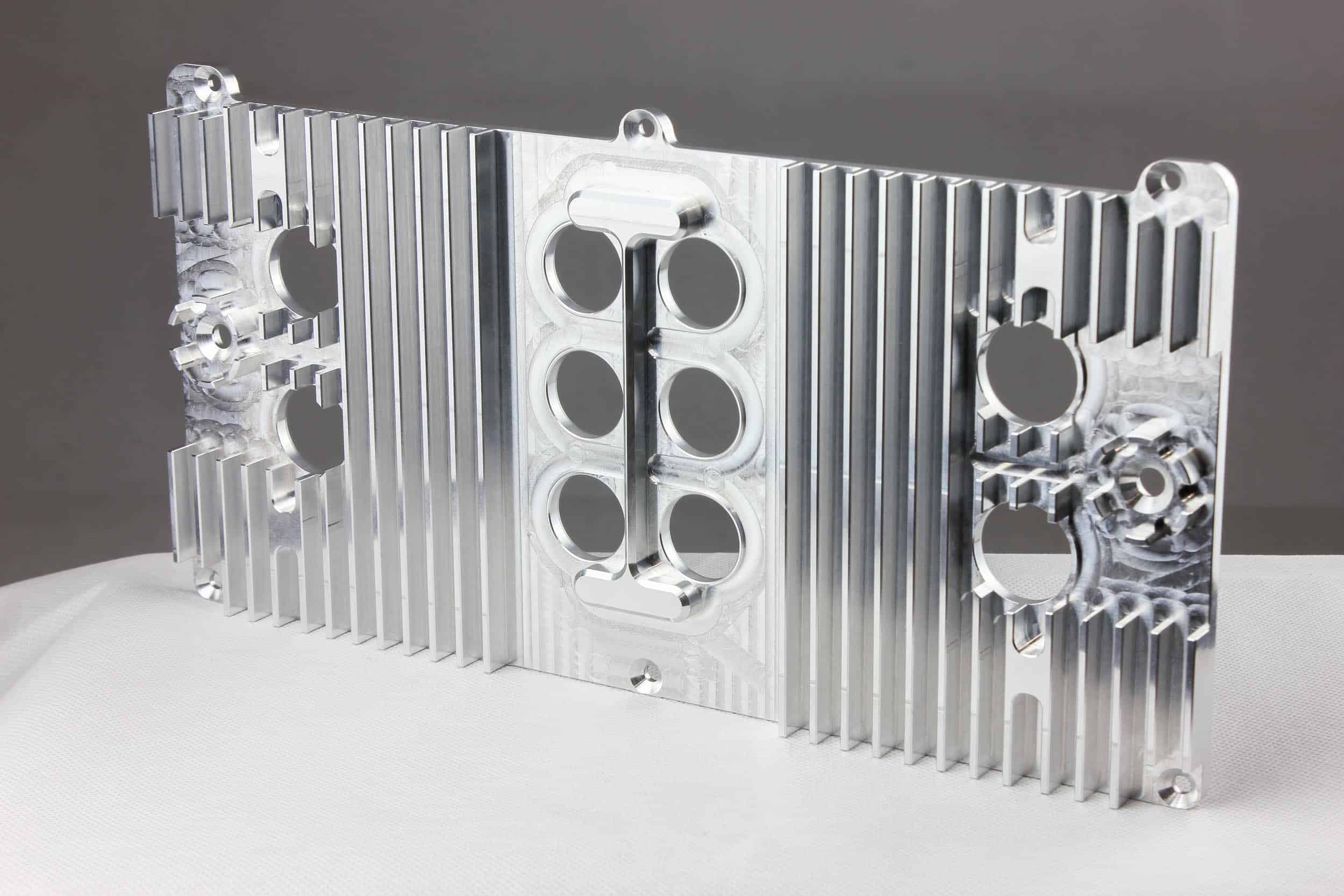

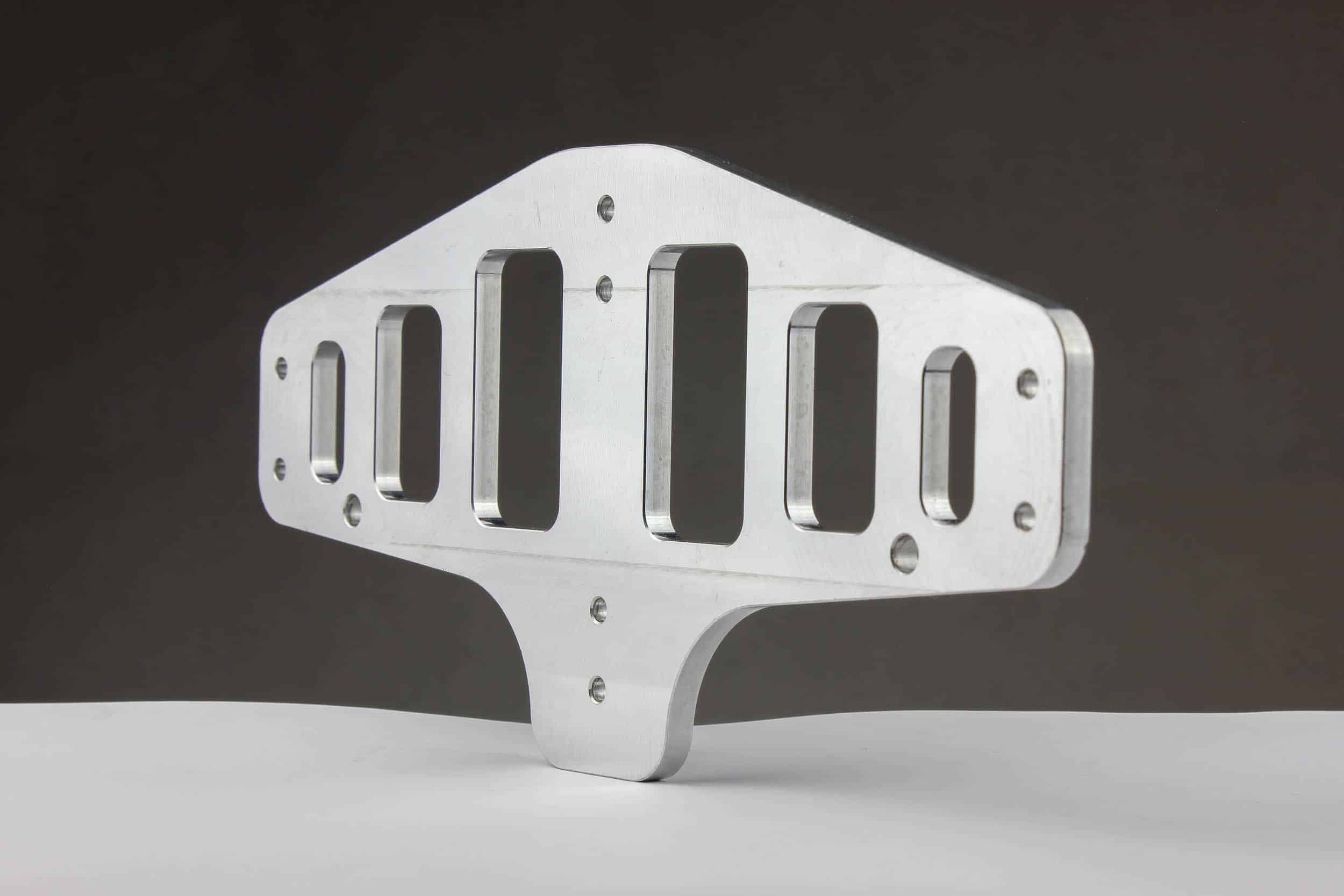

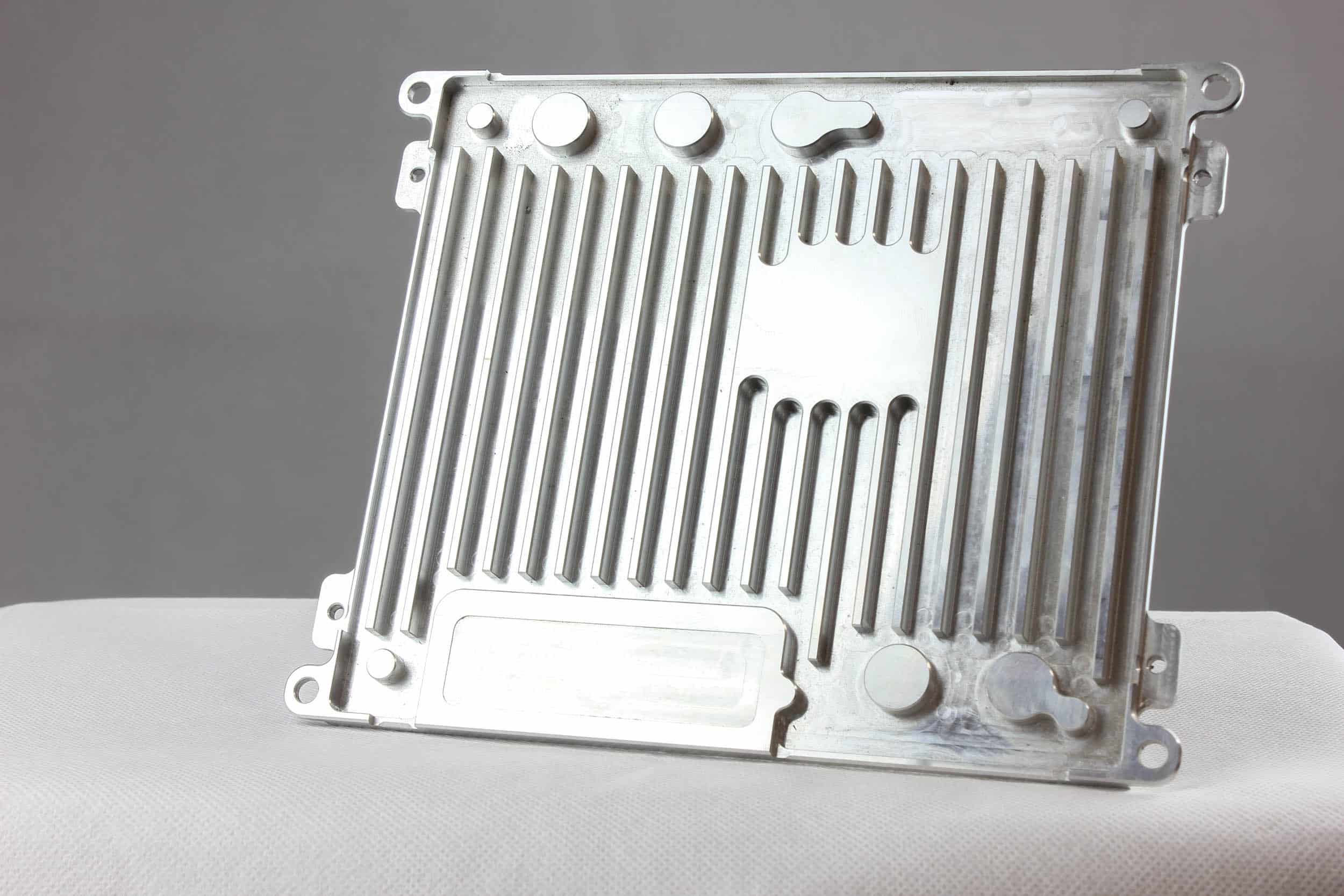

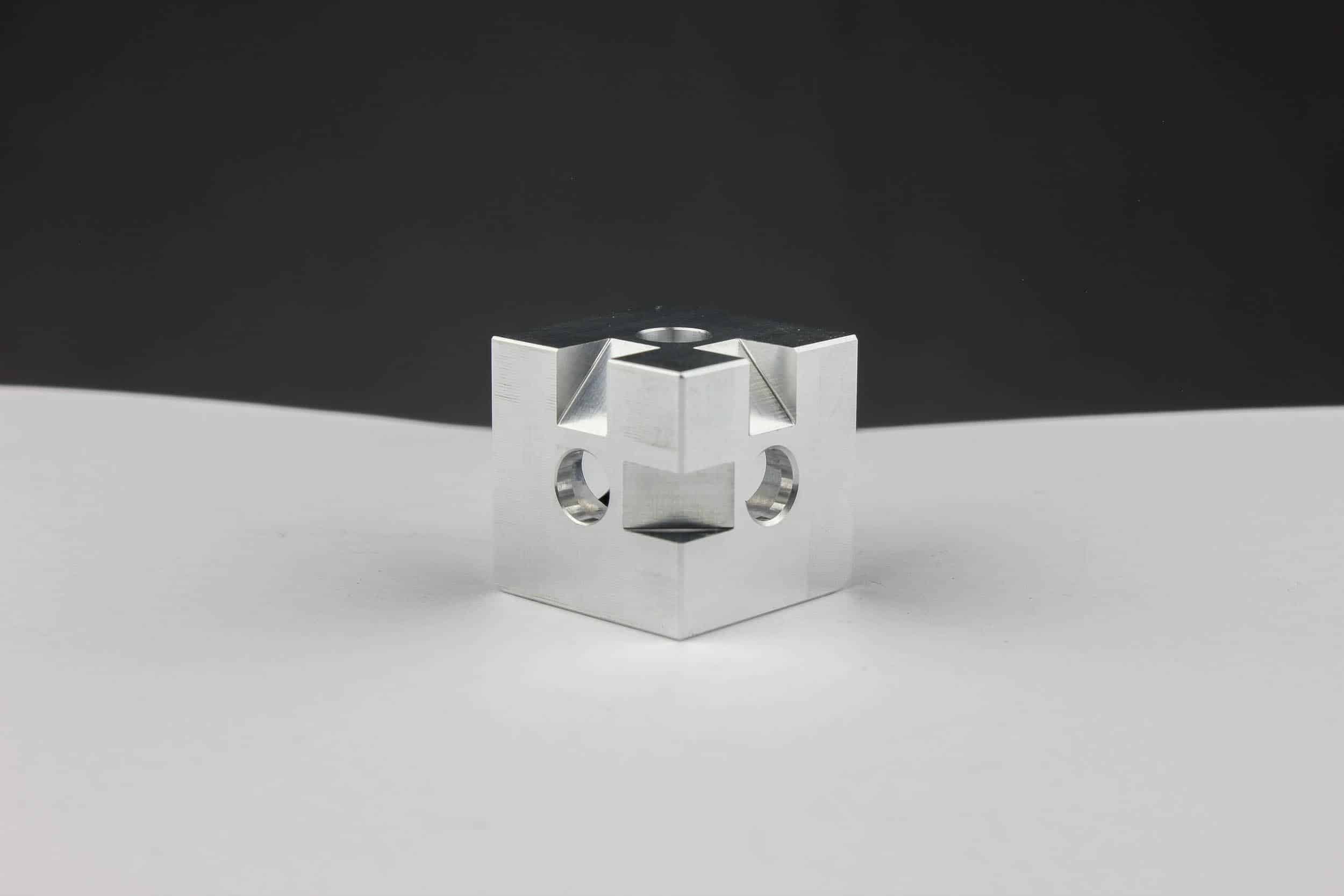

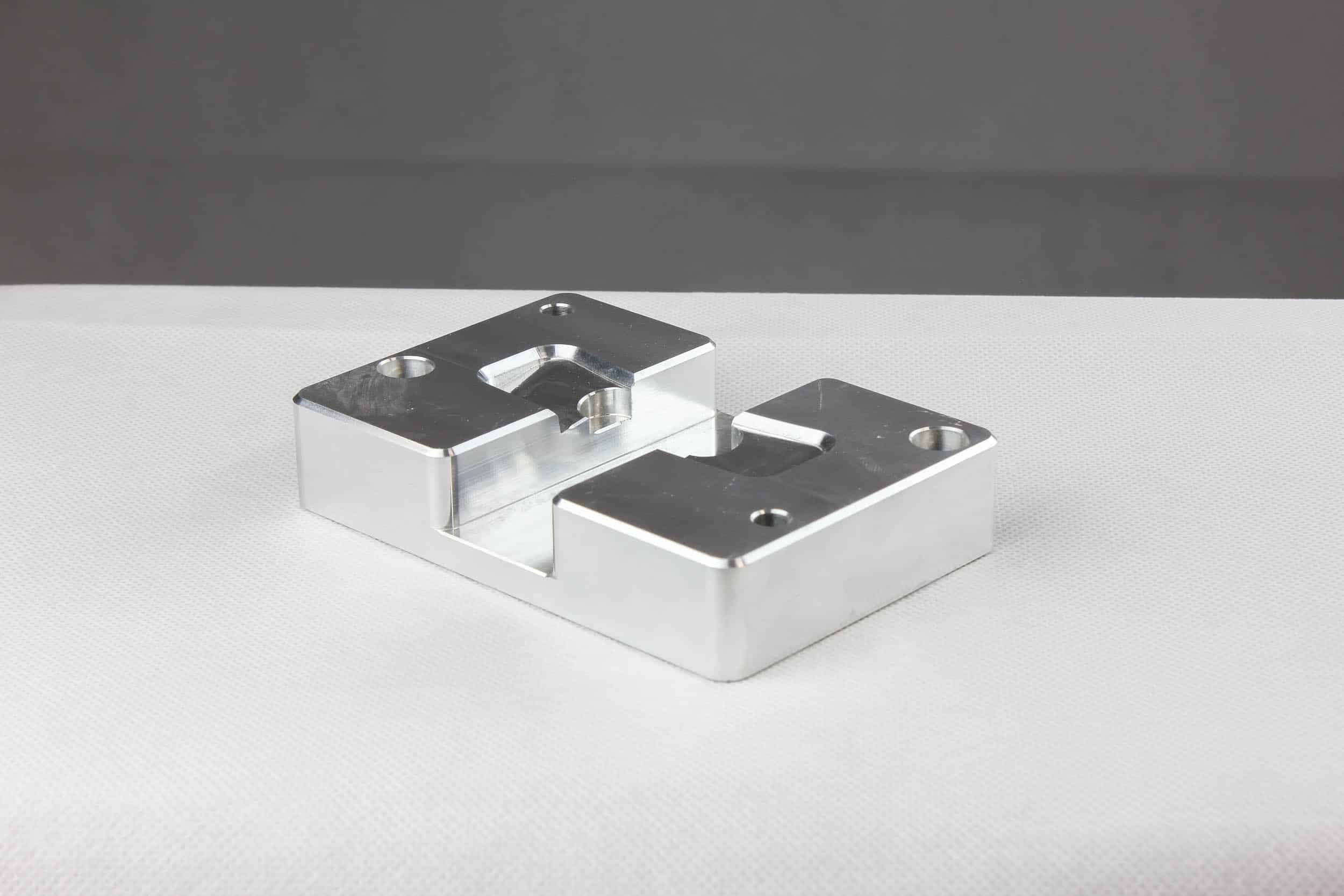

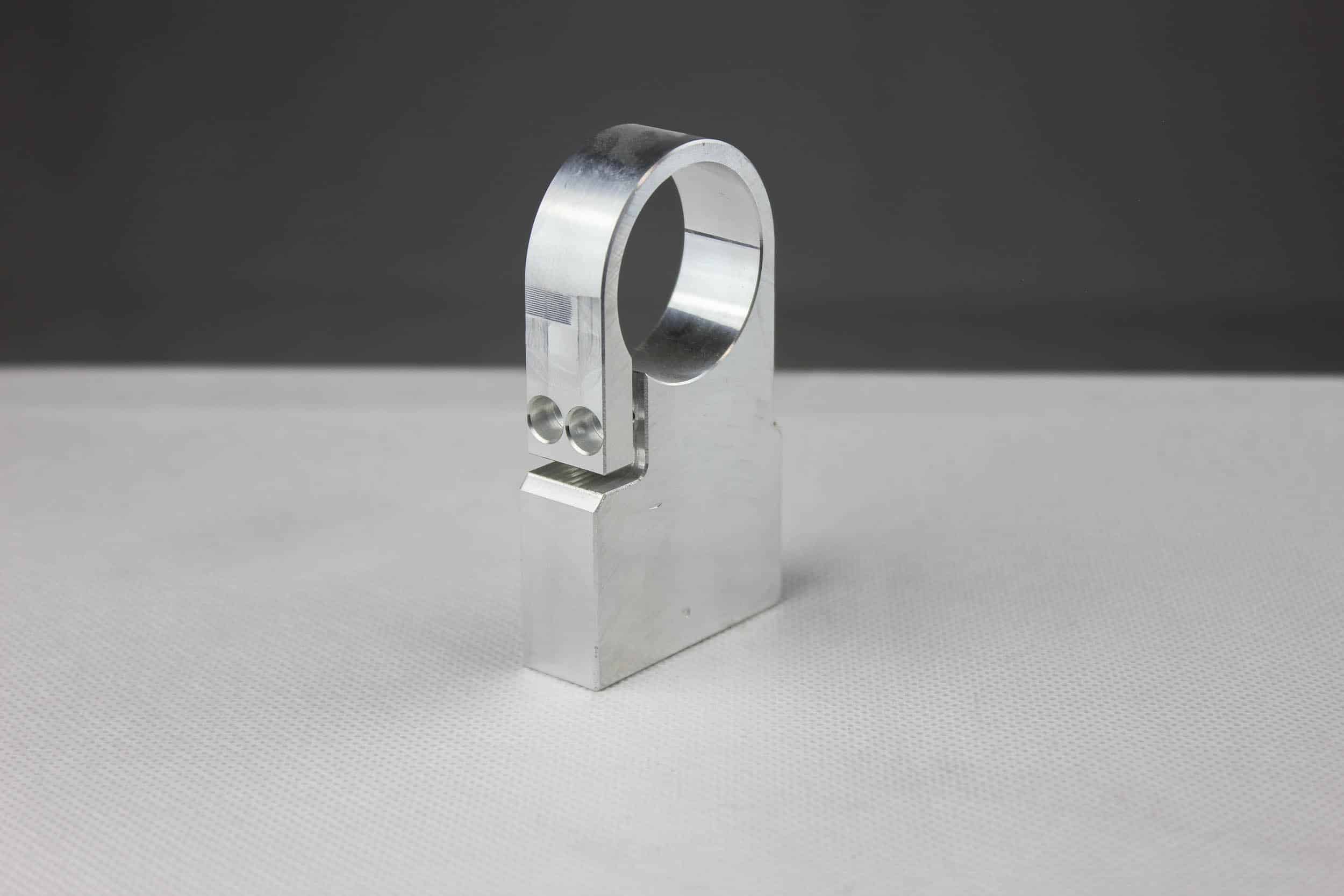

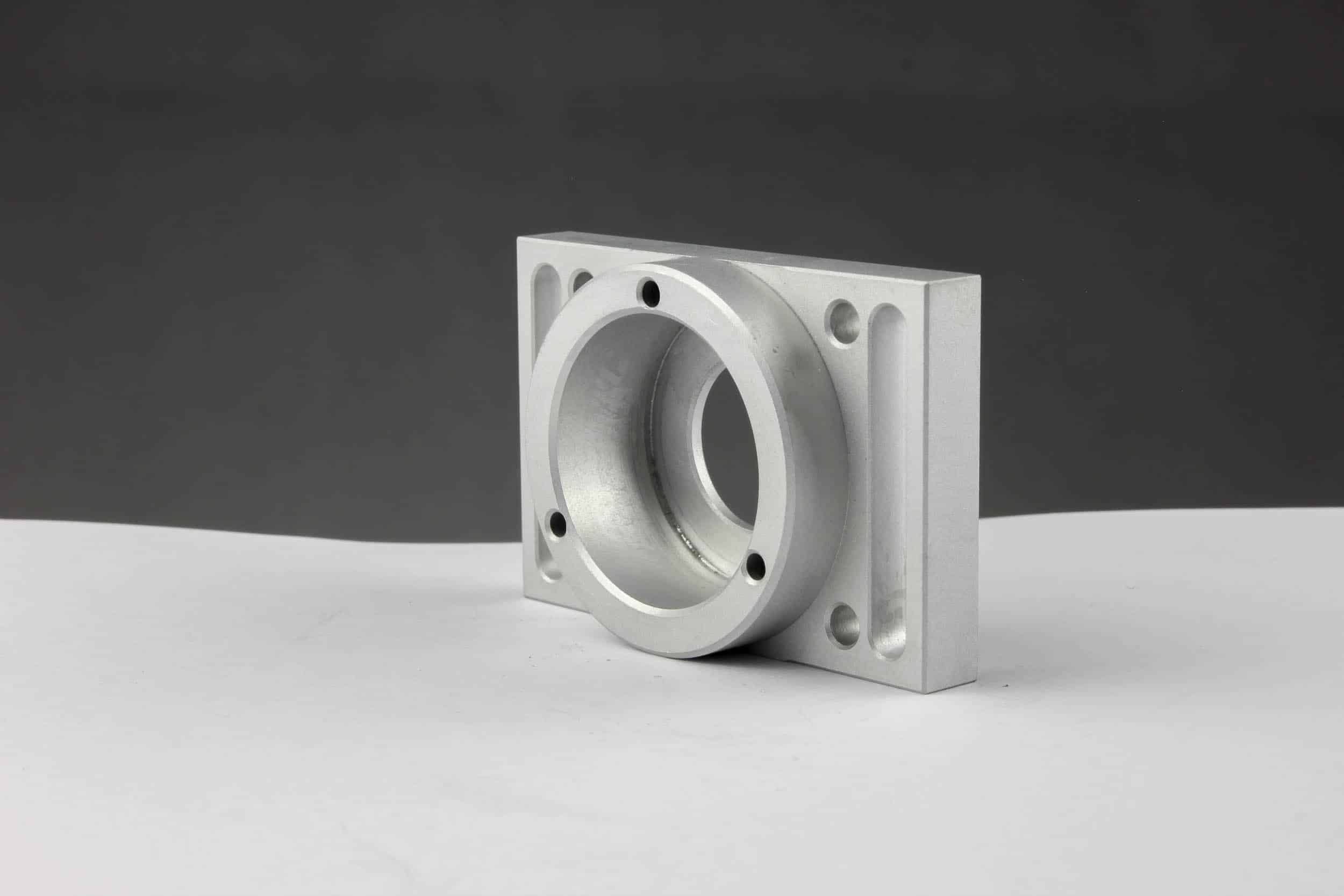

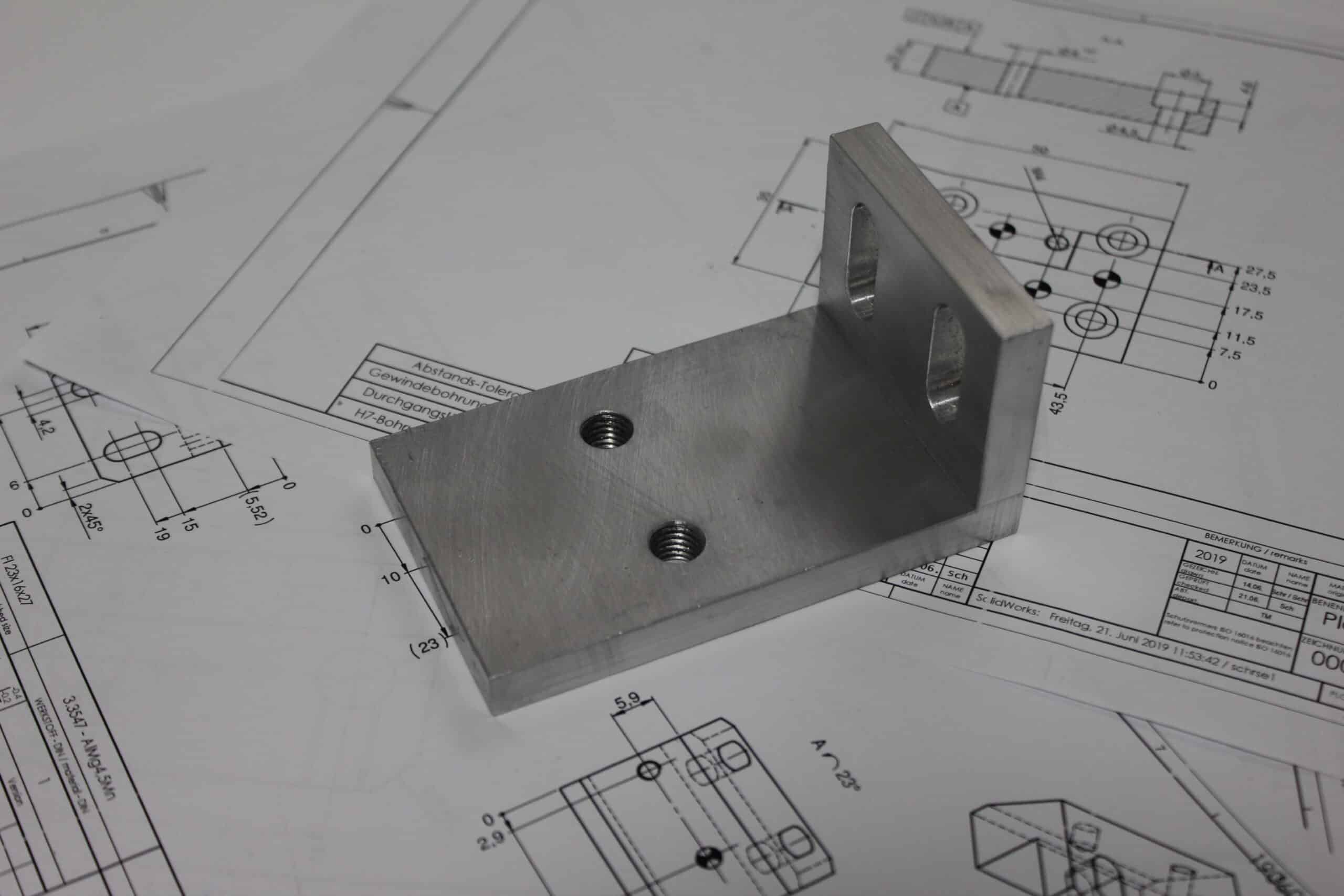

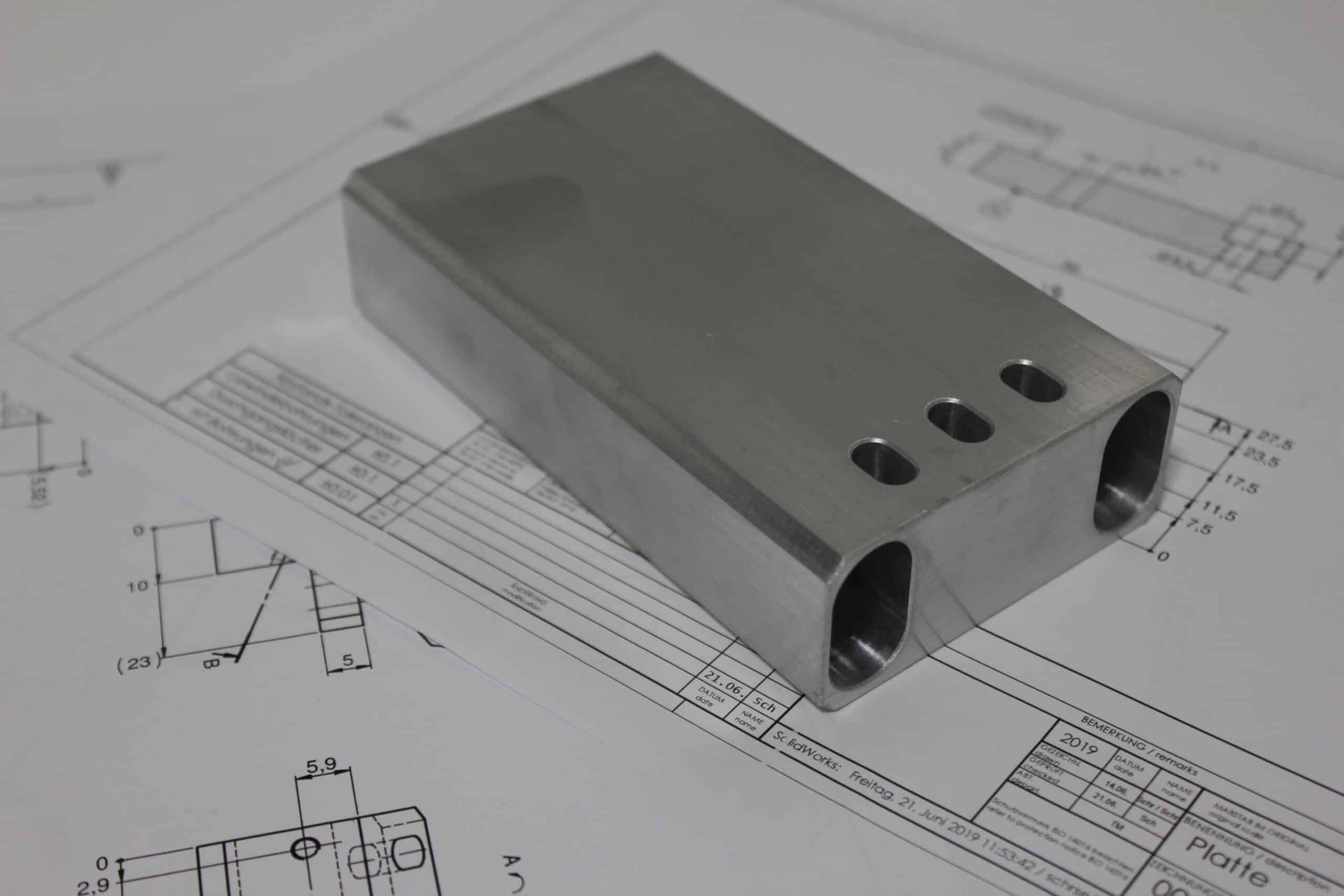

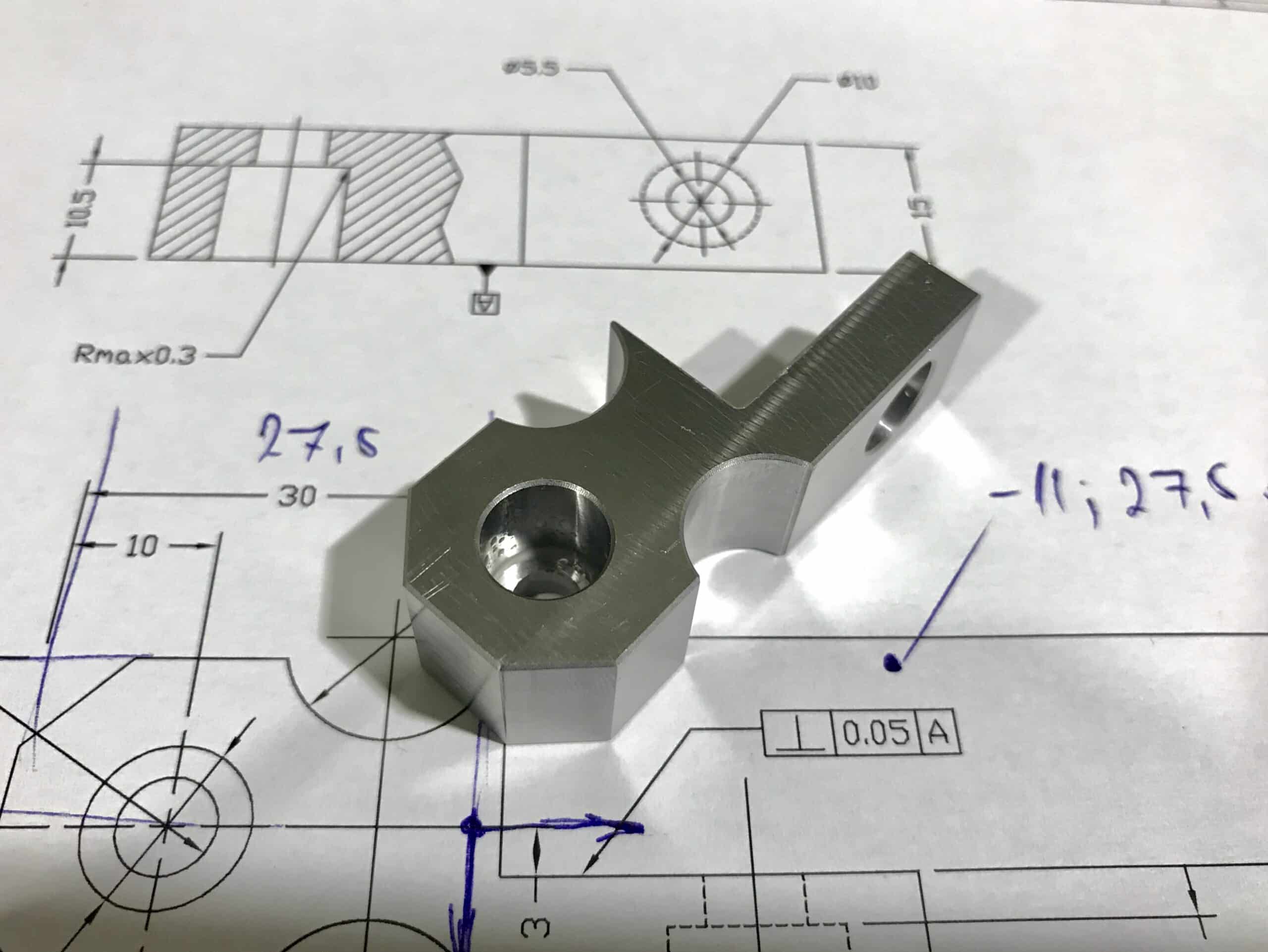

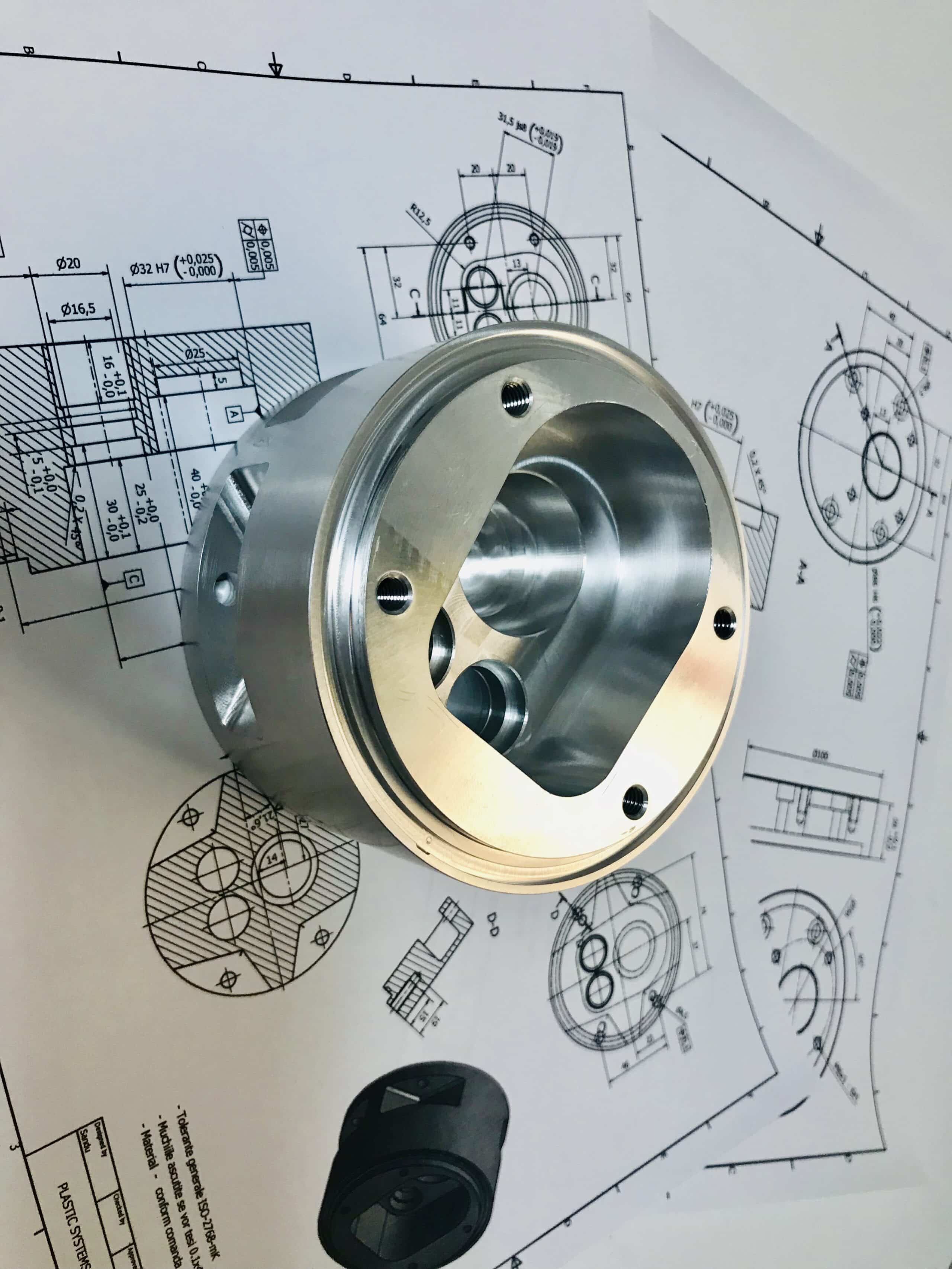

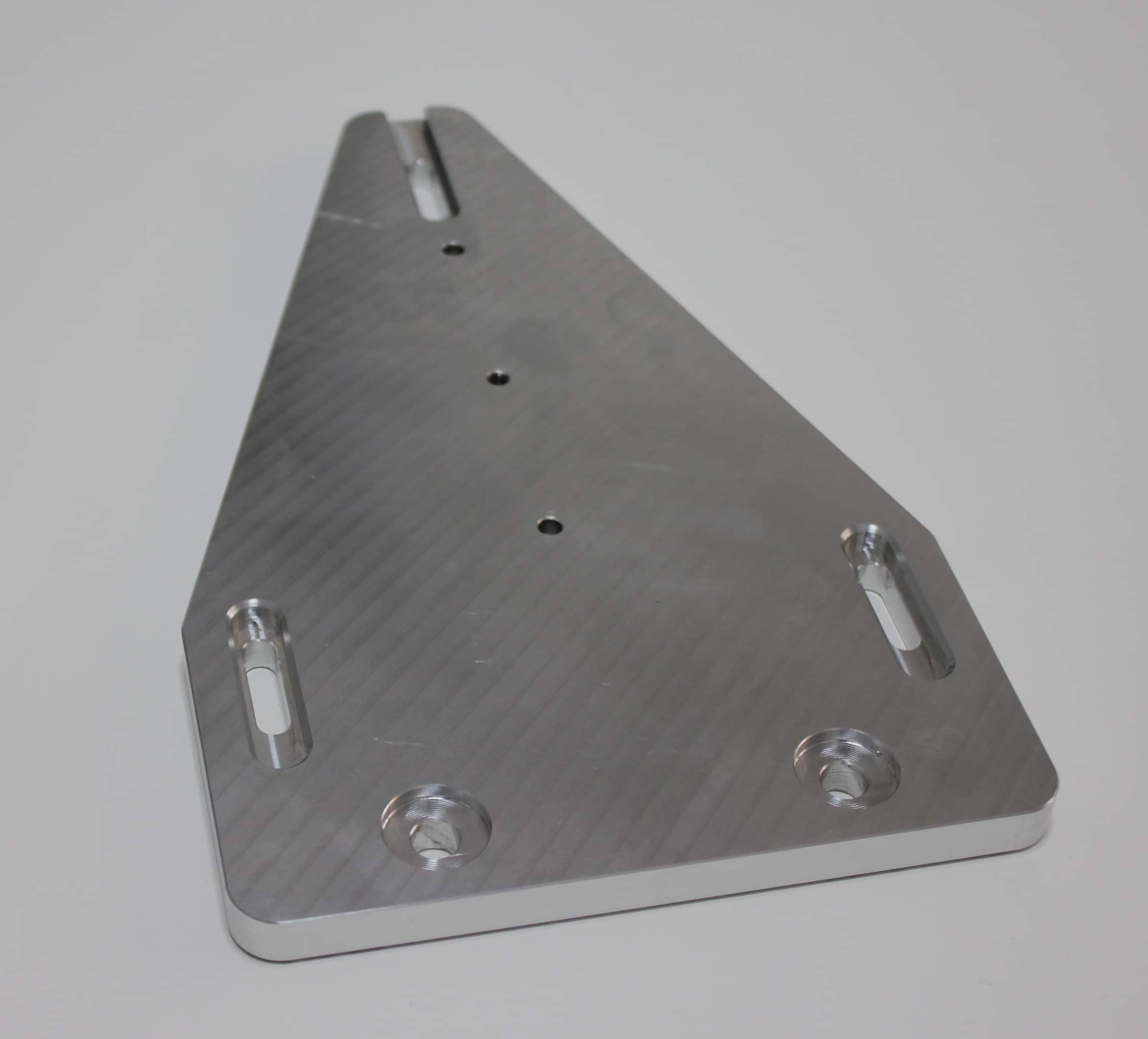

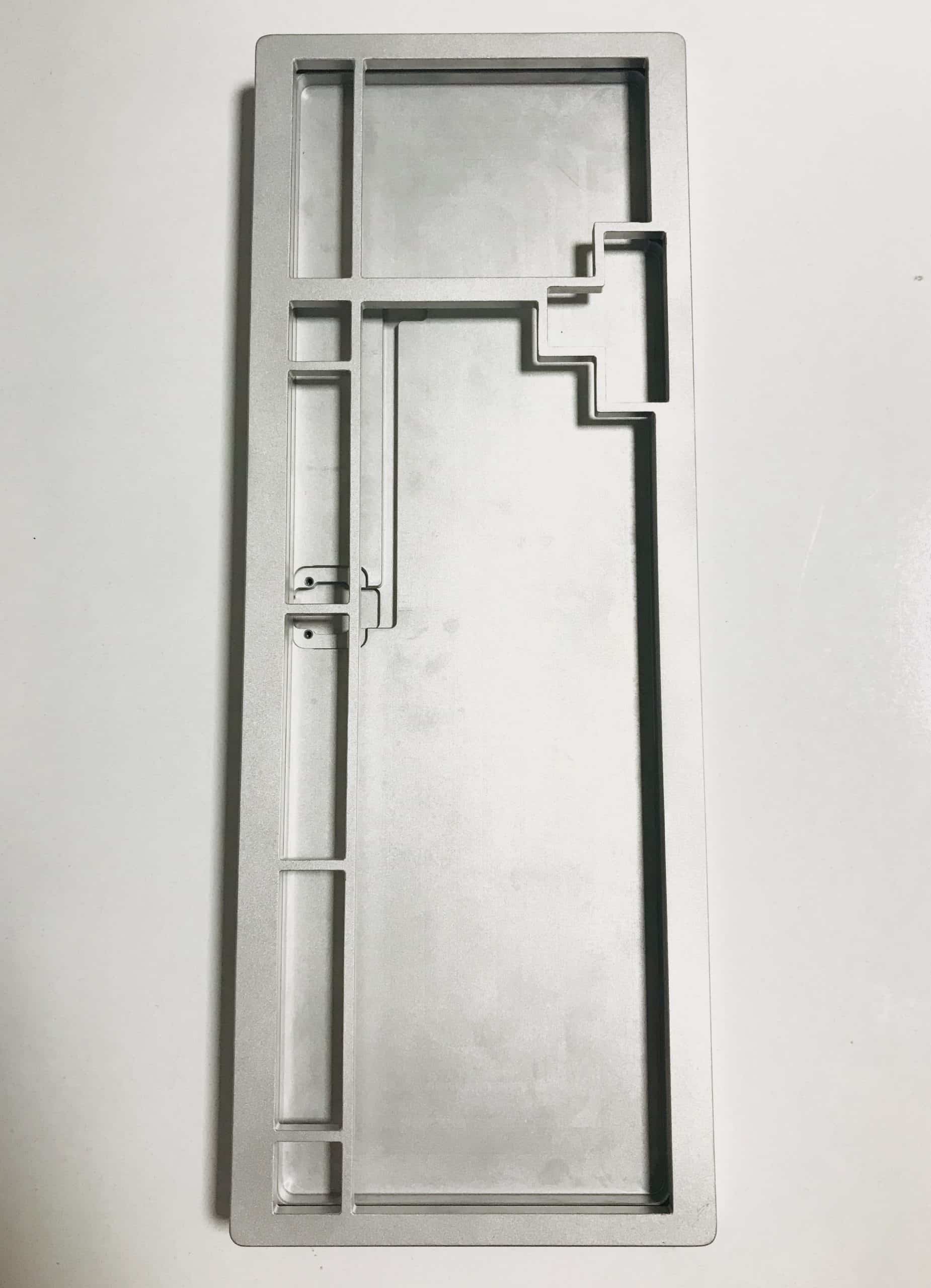

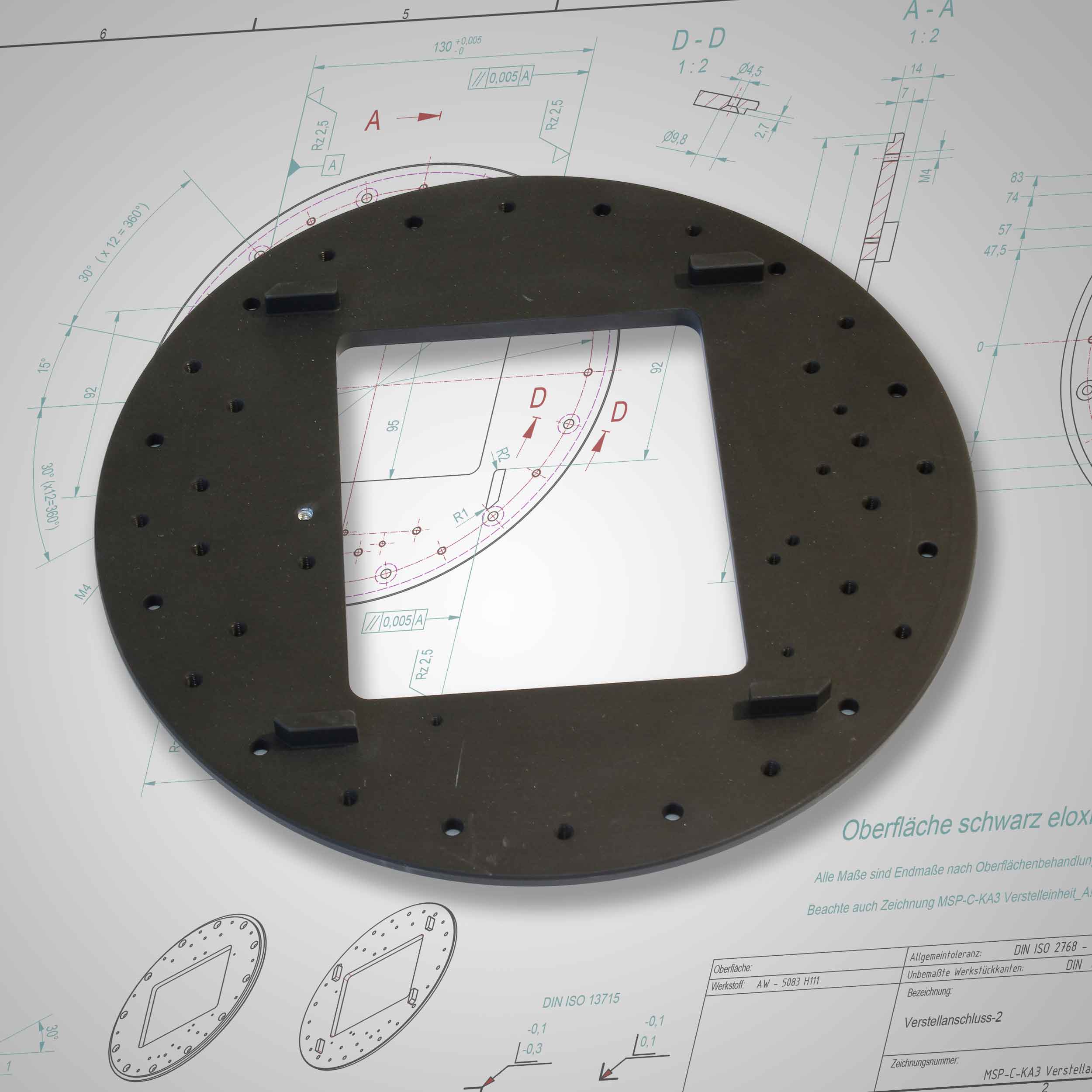

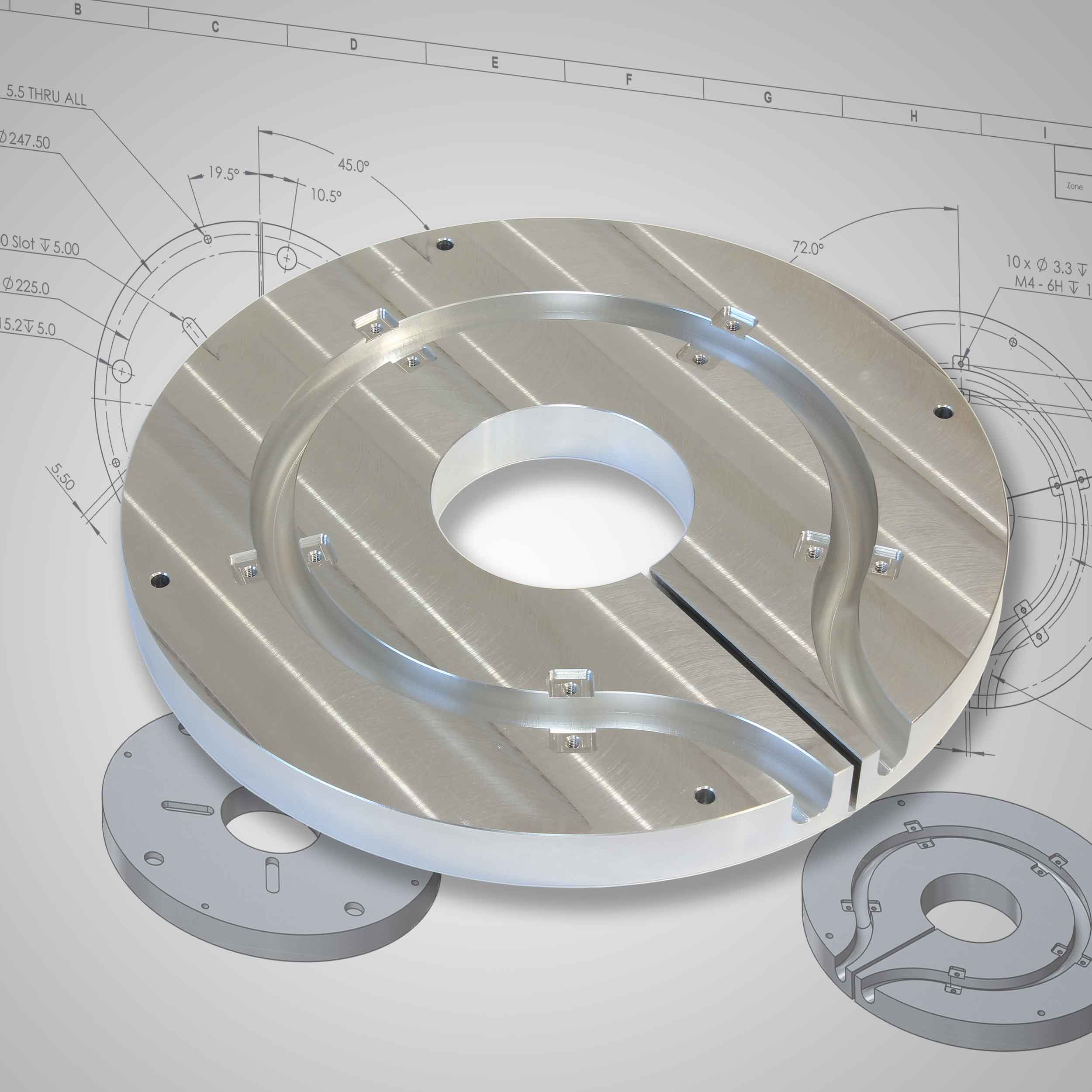

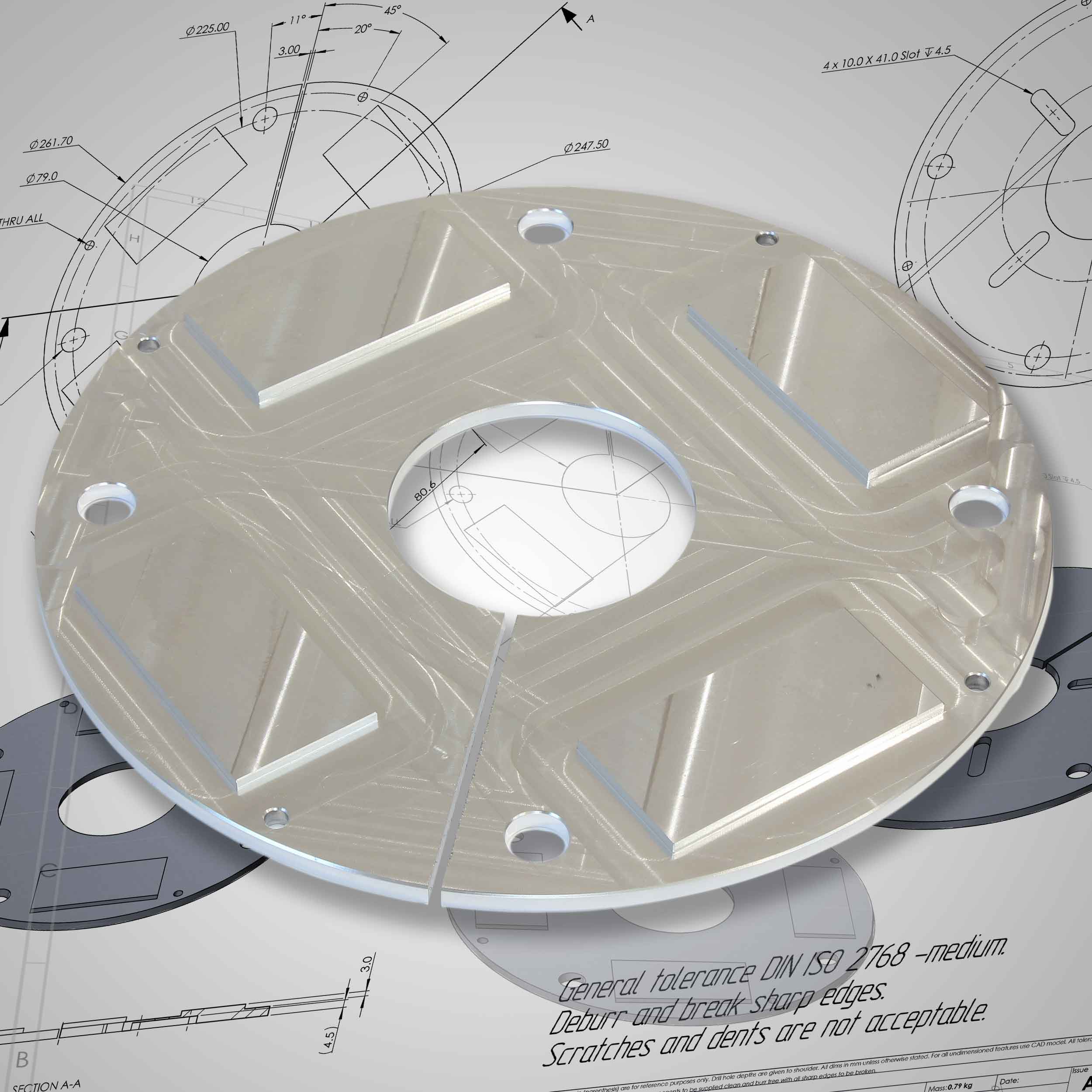

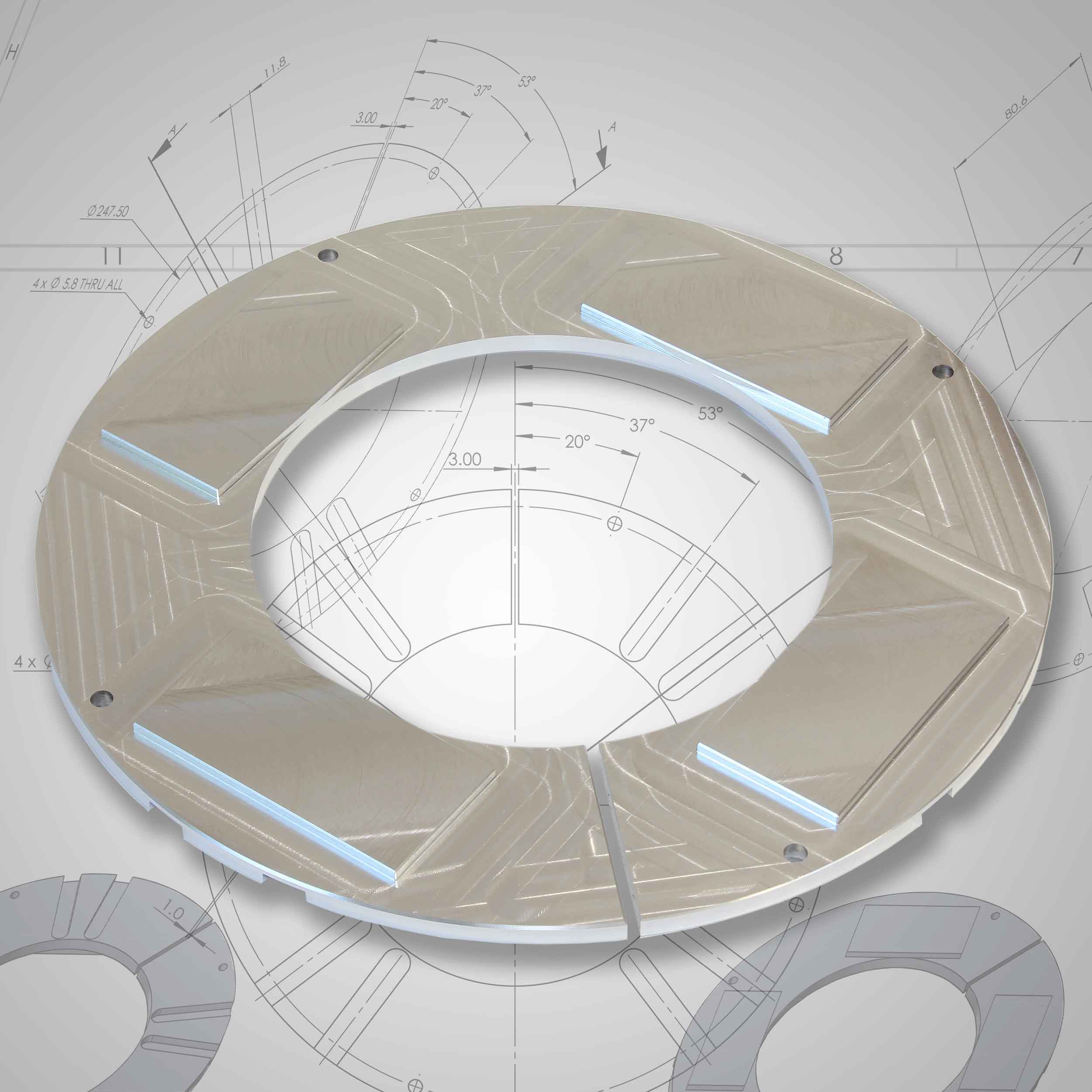

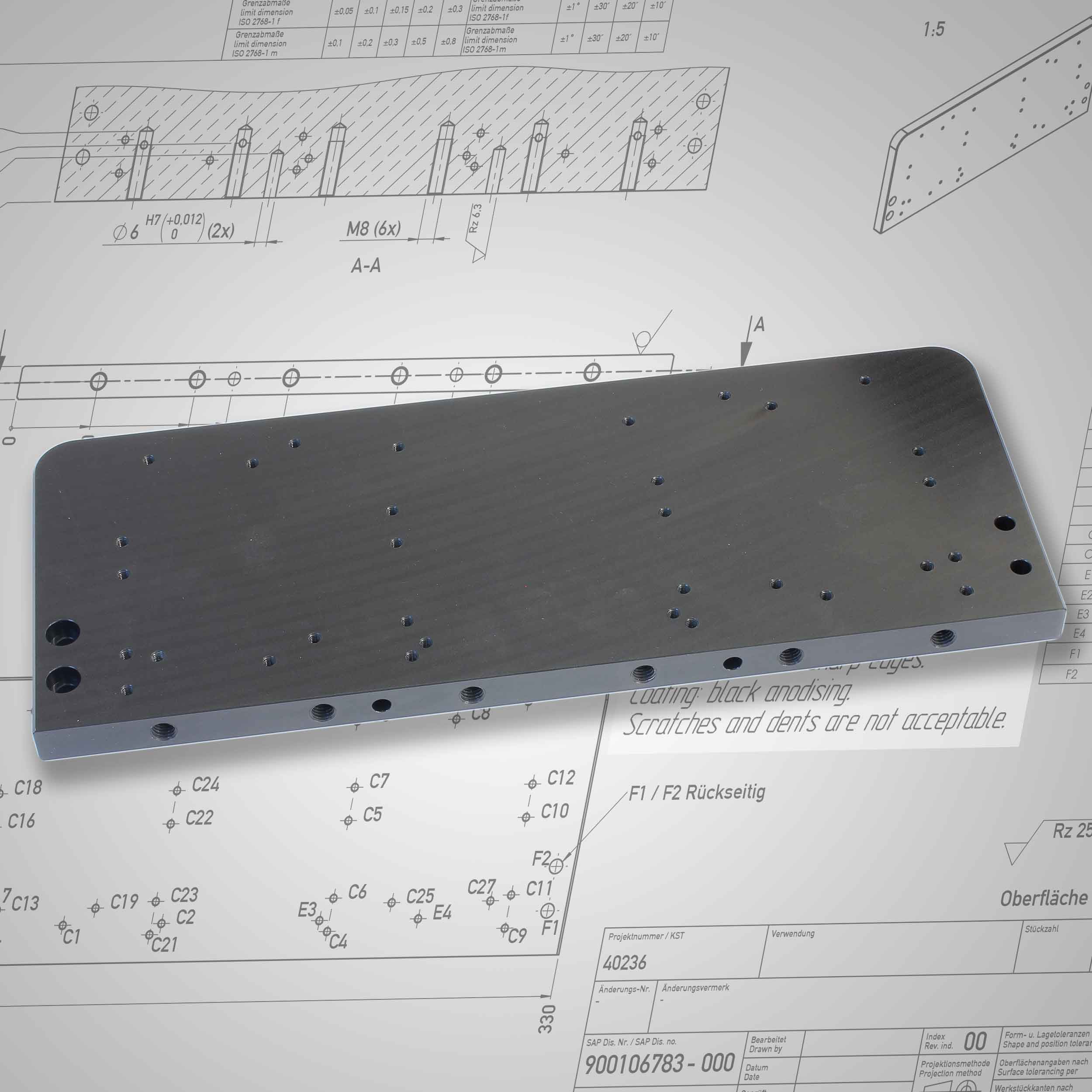

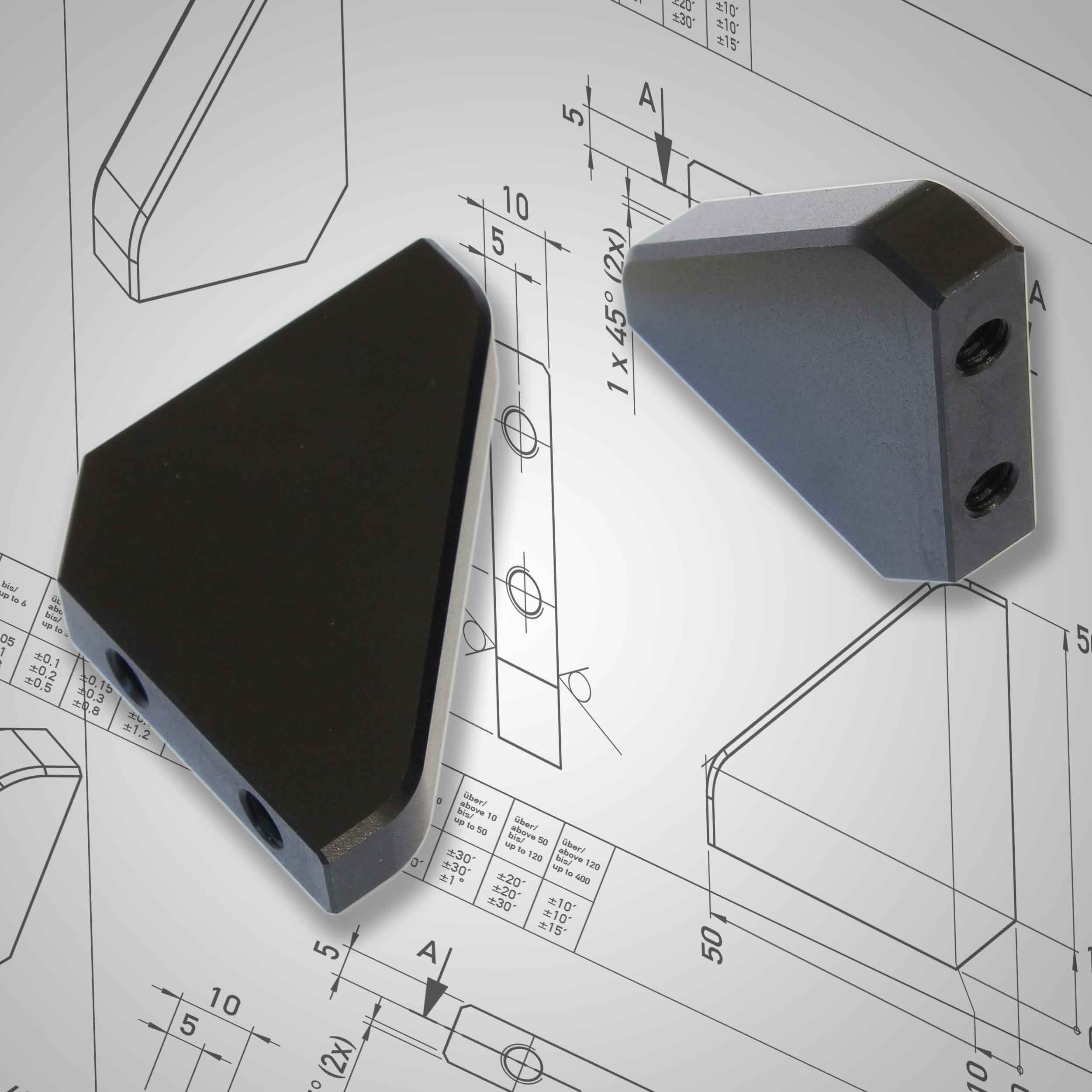

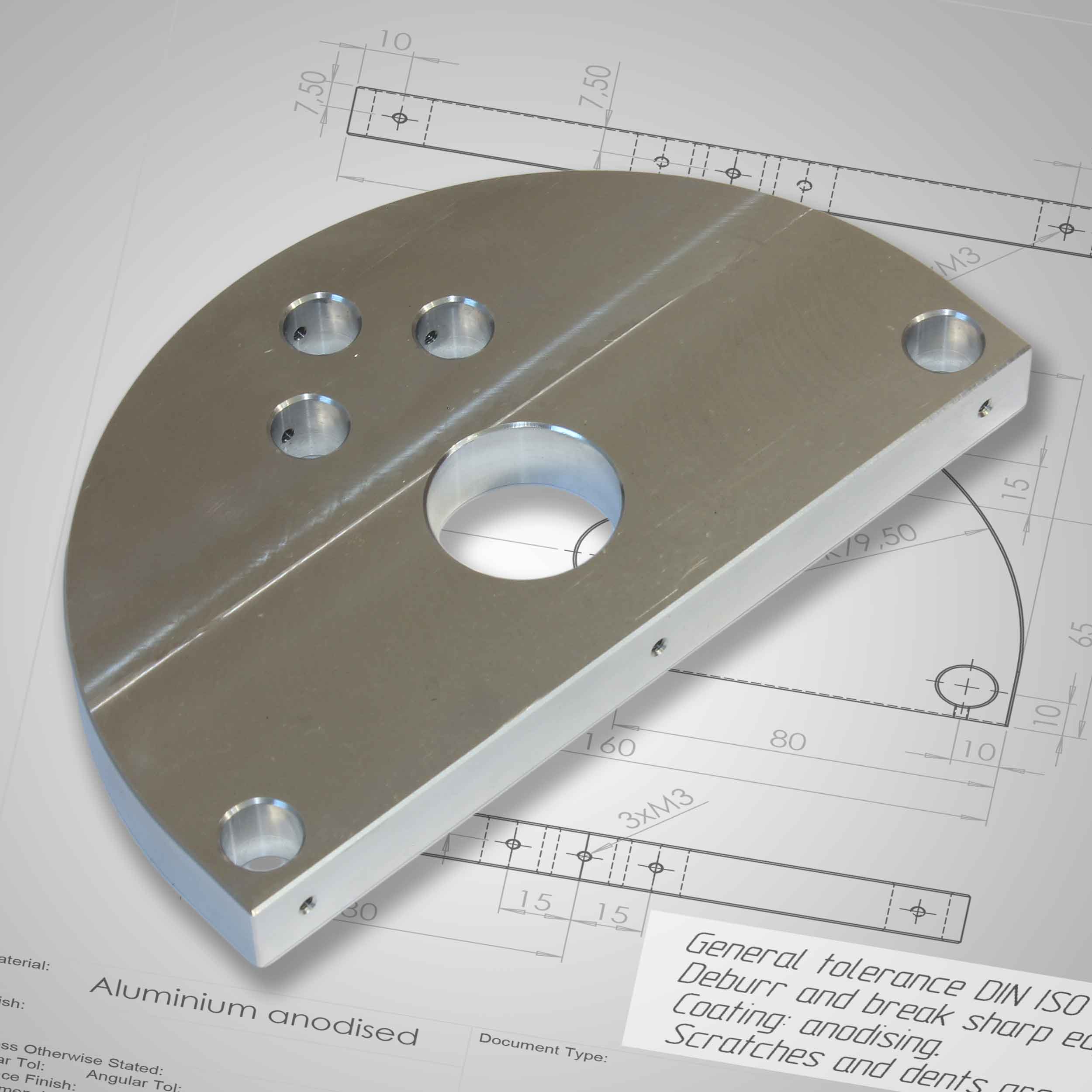

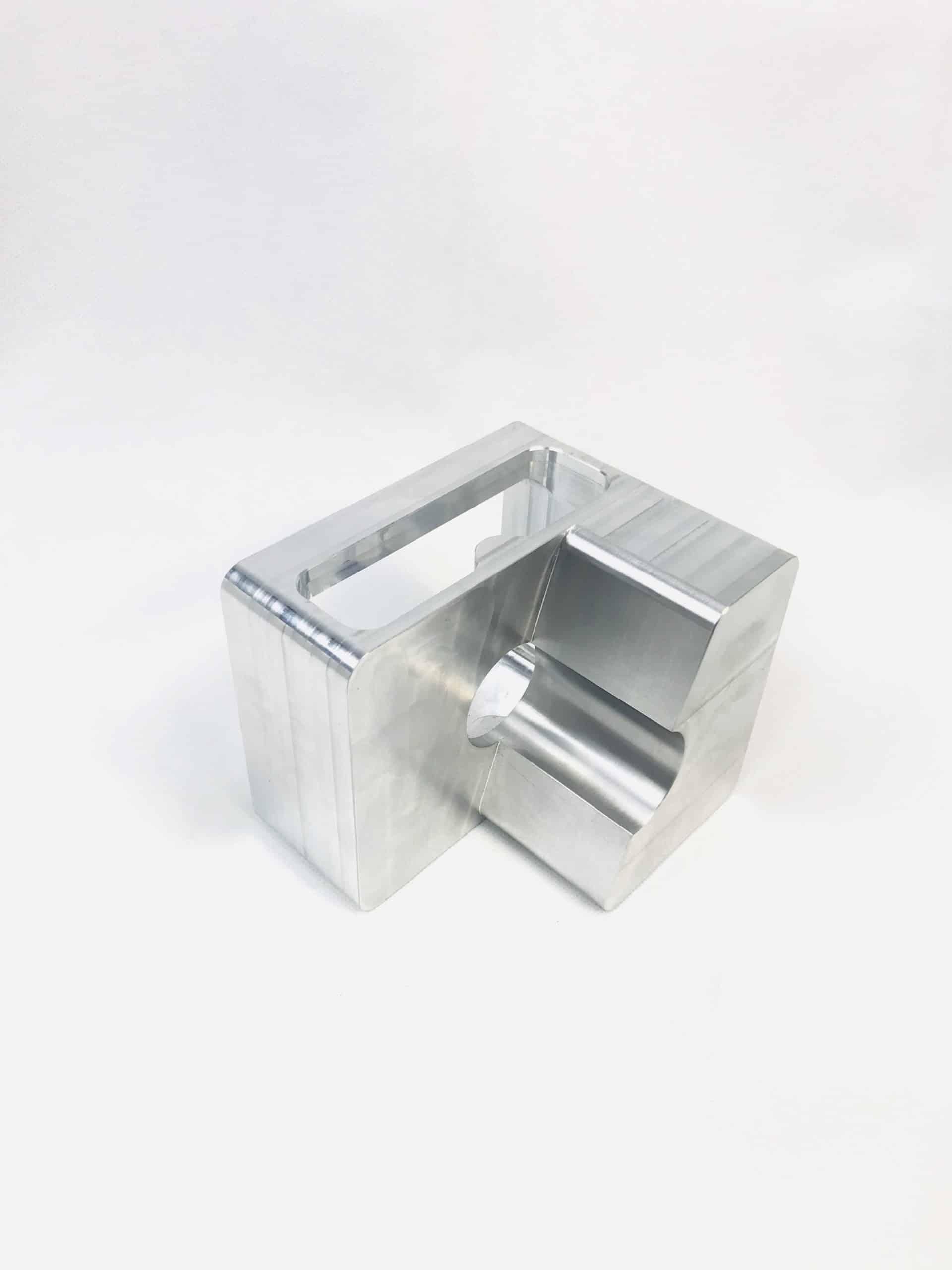

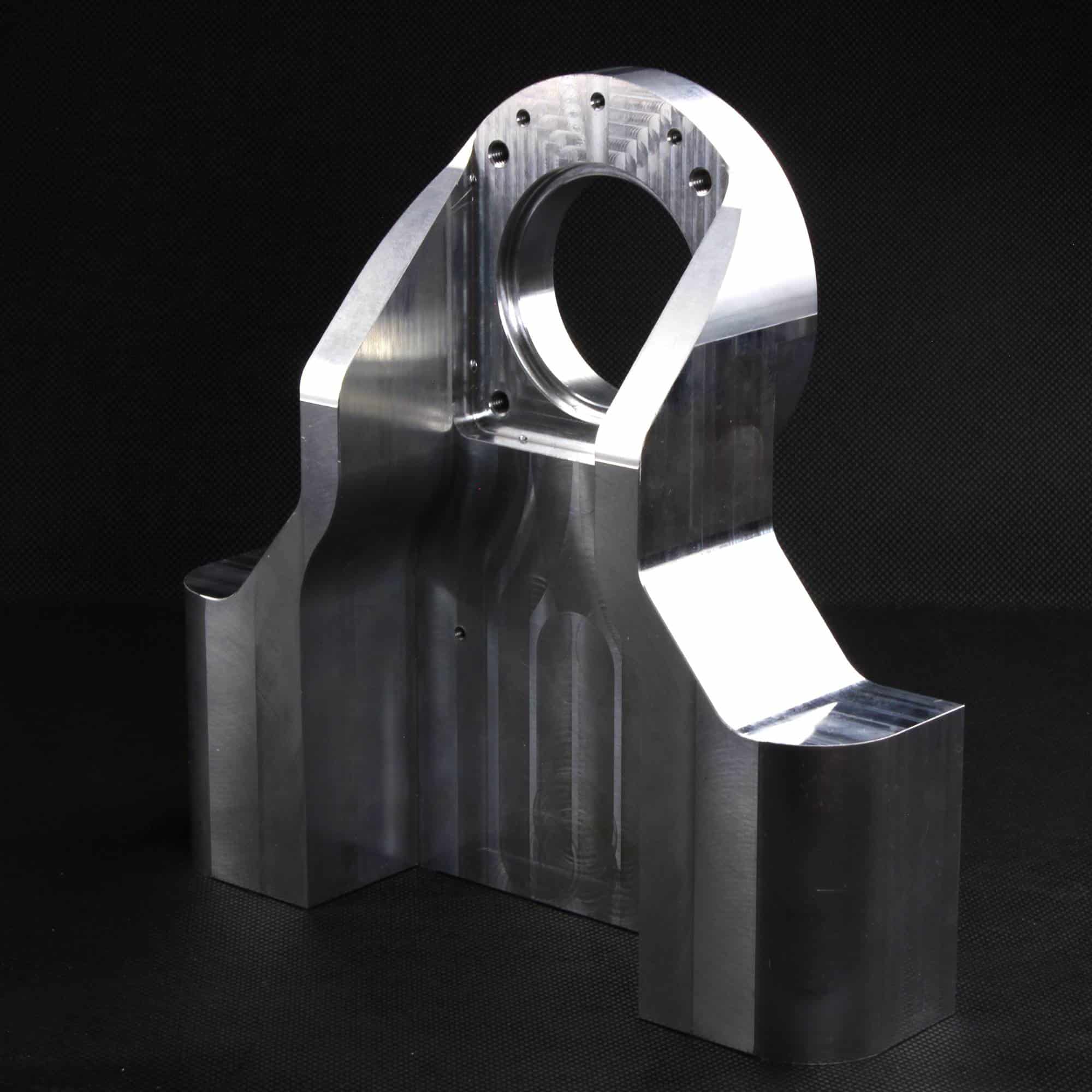

Examples of custom CNC machined parts

post treatments

We provide post-treatment services in-house and through our partners.

Sand blasting

IN HOUSE

This operation is done in our facility to smooth the rough surface, roughen a smooth surface, shape a surface or remove surface contaminants after the parts are machined and ready. By this, we are able to shorten the delivery time substantially and don’t need to rely on third parties.

Anodizing

THROUGH PARTNERS

Through our partners, we can provide anodizing which is a coating applied for the functional and optical improvement of aluminum materials. As a result of the treatment, the surface of the parts changes into a ceramic-like layer, encases the parts and protects them against wear and corrosion. Clients can choose from natural, colored and hard-anodized options.

Heat treatment

THROUGH PARTNERS

We can provide heat treatment for steel parts through partners. This operation is used to alter the physical, and sometimes chemical, properties of a material. To ensure that the measurements are not deviating, vacuum heat treatment is applied.

Laser marking

IN-HOUSE

In our growing bussines, now we can mark a lot of type of metals (steel, aluminium, anodized parts – black or white mark, brass, precious metals) or some other materials like plastic, glass and others on up to a 200 x 200 mm area, even deep in the material.

packaging standards

Our team puts high attention on the details of packaging in order to ensure that the parts are not damaged and arrive to our clients safely. Therefore, we follow standardized steps in the process.

1.

Ensure the ready parts are counted, clean, dry and if needed preserved with anti-corrosion materials before packaging.

2.

Use separate wrapping for each part in case multiple parts are packed in one box.

3.

Sharp edges are protected.

4.

Documentation enclosed: invoice, drawings and signed quality check documentation from engineer who measured the parts.

5.

Empty spaces are filled out in the box to protect the parts from moving.

6.

Every order is packed in new cardboard boxes, however, whenever possible we reuse still new boxes to protect our environment.

7.

Use double sided packaging boxes.

8.

Each shipment is labelled with the order number, drawing and quantity.

SHIPPING

Free world-wide shipping

You don’t have to bother with arranging the shipping. We work together with numerous carrier companies to deliver your order anywhere you are located.